Would you want to learn how cases and bottles made of plastic are created? Consider researching blow molding. This is the method used to make many commonplace items. Bottles and auto components are the two main products produced by blow moulding. Join us as we investigate the many forms and outcomes that this incredible process may take. Anyone can blow moulds with ease and proficiency if they follow this tutorial! It is feasible to begin right now.

What is the process of blow molding plastic?

Melting the Plastic

The procedure begins with little plastic balls shaped like tiny beads. The tool used to load these pellets into it is called a hopper. The heated tank receives pellets that are transferred from the bin. The plastic pellets melt at the barrel’s high temperature. And then turning them into a sticky, viscous liquid. This melting plastic will form the shape of the object.

Forming the Parison or Preform

An approximate replica of the final object is made from the molten plastic. A parison is a long tube created by this liquid plastic via a spherical aperture in an extrusion process. The model, which resembles a small, thick bottle with a screw cap, is created by pumping plastic into a mould. This parison or mould will be blown into the finished form.

Clamping the Mold

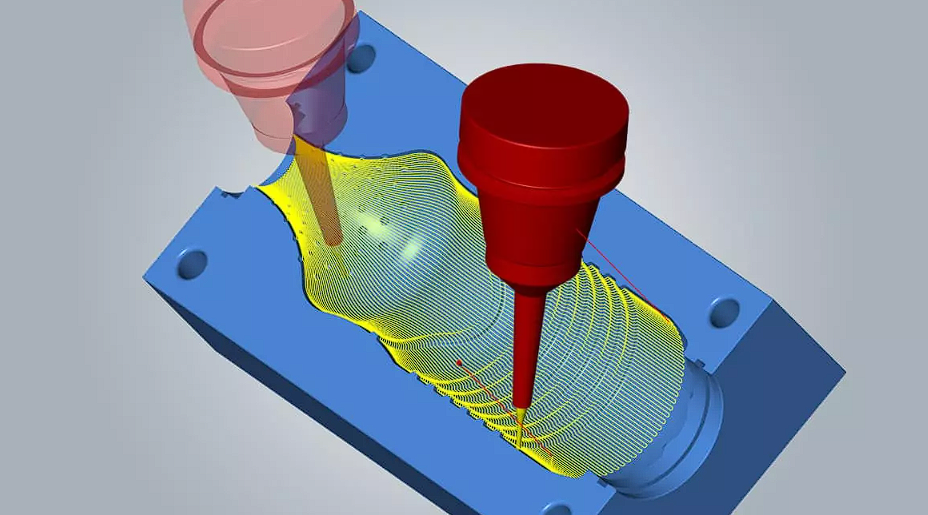

The tool required for this process is called a mold. It resembles a metal shell with two halves that fit together. It has the parison, or model, inside. The final product takes on the form of a mold and is often a bottle or other container. Once the mould is sealed around the parison or model, it is securely held and prepared for the next phase.

Blowing Air

The pair may then be executed or inflated using a vent or blow pin. The parison expands by filling the tube with air, much like a balloon does. The sculpture has the suppleness required to fit the mould because air has been blown into it. The air pressure causes the flexible plastic to adhere to the mould’s edges. And take on the precise form of the mould.

Cooling

After being blown into form, the plastic has to cool down to solidify. There may be holes in the mould that let in cold water. The plastic would cool down more quickly if this were done. As soon as the plastic begins to solidify, it adheres to molds. Most importantly, cooling the object down ensures that it maintains its form.

Ejecting the Product

Once the plastic has cooled and solidified, it may be removed from the mould. Remove the completed product from the mould, which resembles a bottle or jar. You may sometimes need to trim away excess plastic. Removing this excess plastic part, known as “flash,”. It is standard practice to improve an object’s look.

What are the uses of blow mold plastic?

People use blow moulding plastic to create a wide variety of commonplace items. This company produces plastic bottles for beverages, toiletries, and shampoos. Large water bottles, food storage bins, and car gasoline tanks are among these items. It is used to produce air tubes and fluid tanks for automobiles. Needles and blow-molded plastic medical containers are regular equipment in hospitals and clinics. A few items made using this plastic include patio furniture, sports tools, and toys. Products made using this technique are lightweight, durable, and competitively priced. Being able to blast mould commonplace items is a great benefit.

What are the different types of blow mold?

Injection Blow Molding

- How it works: The process of these involves inserting plastic into a mould to create a cast. It is a tiny, dense object. The sculpture is then blown air into to grow and approach the final form.

- Uses: Makes perfect little storage containers, such as medicine bottles and cosmetic jars.

Extrusion Blow Molding

- How it works: Once melted, it becomes a tube. When air is introduced into the tube, it eventually fills the mould as it expands. The completed product is removed from the mould after it has cooled.

- Uses: It is particularly useful for large items like milk jugs and shampoo bottles.

Stretch Blow Molding

- How it works: Like injection one, it simultaneously compresses and inflates the work. The result is a better and clearer final product.

- Uses: Sturdy but lightweight water and drink bottles are made from this material.

Injection Stretch Blow Mold

- How it works: Combining injection and stretch blow moulding is the key. A mould is first created, and then the finished form is blown and stretched.

- Uses: You may use it to make clear glasses for soda and juice.

Extrusion Stretch Blow Mold

- How it works: This process combines bending, extrusion, and blow moulding. First, the tube is shaped by pushing and stretching it.

- Uses: It may be used to build large items like water bottles.

Each of these ways is used in the making of commonplace plastic containers, cups, and other items.

What is the best place online to blow mold plastic?

Do you want to know where I can get the greatest instructions for blow moulding plastic? Browse through EX MOULD Co., Ltd.’s website. Its content is both easy to grasp and helpful. Everything from the basics to the most current news in the business may be found here. This website caters to players of all ability levels. Because it is user-friendly, this website is simple to navigate. You can get the best information on blow moulding plastic right here on this website.

Last remarks

You know how to blow mould plastic at this point. They create it nicely, and we use it every day. Anything from drink containers to auto components may be made using blowing moulding. Heat softens plastic, and air is injected into molds to create the items we need. Shampoo and pop bottles, among many other things, may be produced with blow moulding. It facilitates our lives and is an essential component of the way things operate.