Introduction

Blow molding is a cool way to make lots of different plastic stuff. Imagine it like a magic trick for making things out of plastic! In the middle of this magic is something called a “parison.” This guide is like a fun story that will tell you all about the parison and why it’s super important in making cool plastic things. We’ll talk about how it works, the different types, and where we see these plastic wonders in our everyday lives. So, get ready for a plastic adventure as we explore the world of blow molding and the amazing parison!

What is blow molding?

Blow molding, a widely used manufacturing process, is particularly effective for crafting hollow plastic items, such as bottles and containers. The process begins by melting plastic, which is then shaped into a tube known as a parison. Wind is fired into a mold after the parison is added, forcing the plastic to conform to the form of the mold. The finished product is allowed to cool down after it develops and then pulled out of the mold. This versatile technique is chosen for its efficiency in producing a diverse range of lightweight and durable plastic products, making it a key player in various industries, including packaging and automotive.

What is a parison in blow molding?

In the realm of blow molding, a parison is a significant element—a hollow tube-shaped structure formed from molten plastic, acting as the starting point in the manufacturing process. This tube is created by extruding molten plastic and serves as the foundational material for crafting the final product. The parison’s design, length, and thickness are carefully considered, as they profoundly influence the eventual shape and characteristics of the end product. As the parison is placed in a mold, it undergoes a transformative process where compressed air is introduced, causing the plastic to expand and conform to the mold’s shape. This method is widely employed for producing a diverse range of products, from bottles to containers, owing to its efficiency and versatility in creating lightweight and durable plastic items. Understanding the role of the parison is crucial for appreciating the intricacies of blow molding and its applications across various industries.

What is the role of a parison in blow molding?

In blow molding, think of the parison as the starting point—it’s a hollow tube made from melted plastic that decides how the final product will look. After forming the parison, it goes into a mold, and when compressed air is added, it takes the shape of items like bottles and containers. Simply put, the parison sets the scene for molding in the blow molding process, shaping the end result of our plastic products.

The types of parison

The type of parison used depends on the manufacturing process and the desired end product. Here are some common types of parison:

Extruded Parison:This parison is created by extruding molten plastic or glass through a die, resulting in a continuous tube of material.

Usage: Common in processes like extrusion blow molding for plastic containers.

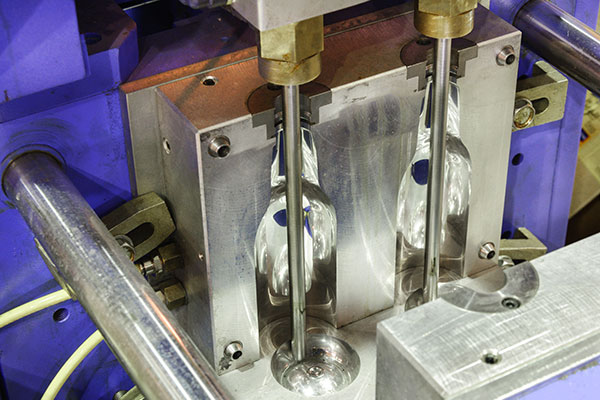

Injection-Blow Parison:The parison is created by injection molding, forming a hollow shape that is later blown into its final form.

Usage: Often used in the production of small, intricate bottles or containers.

Injection-Stretch-Blow Parison:A two-step process where the parison is first injection-molded and then stretched and blown into its final shape.

Usage: common in the production of PET bottles for beverages.

Tube or Seamless Parison:A seamless tube of plastic or glass is created using methods like ram extrusion or tubing processes.

Usage: Found in certain glass blowing techniques or in specific types of plastic molding.

Gob or Gathered Parison:In glass blowing, a piece of molten glass is collected on the end of a blowpipe or rod to form the initial shape.

Usage: Traditional method of glassblowing for creating various glass objects.

Rotational Molding Parison:This involves placing a measured amount of powdered or liquid resin in a mold, which is then rotated to coat the interior and create a hollow part.

Usage: Common for large, seamless plastic products like tanks and containers.

Eco-Friendly Ways

As sustainability gains prominence, the blow molding industry is adapting by incorporating eco-friendly practices in parison manufacturing. This section explores the eco-conscious initiatives shaping the future of blow molding.

Dig up more about blow mold

After an extensive talk about “What is a parison in blow molding?” we now know much more than before we got started. However, there is still more to understand about blow molds, so the genuine query at hand is: How can we acquire the most knowledge about blow molds? Dont worry, we have the best way and that is the website of EX MOULD Co., Ltd. Here, you will find the perfect information you need. So dont be late to visit the website of EX MOULD Co., Ltd

At Conclusion

In simple terms, knowing What is a parison in blow molding? is super important for anyone curious about making plastic stuff. Whether you’re just starting out, dealing with common problems, or dreaming up cool new ideas, getting the parison right is the key to making awesome plastic things with blow molding.