Blow molds are super important in our world today. They’re the magic behind many plastic products we use every day, like bottles and containers. Making these molds is a special skill, and it takes a team of experts to do it right. Companies like moldplasticinjection.com are stars in this field. They have designers, engineers, and technicians who work together to create these essential molds. Their expertise turns simple ideas into real, useful products. Without blow molds, we wouldn’t have many of the convenient and necessary items we rely on daily. These molds play a huge role in our everyday life!

What is blow mold?

Blow molding is a cool process used to make hollow plastic parts, like bottles and containers. Here’s how it works: First, manufacturers heat plastic until it’s soft. Then, they put this soft plastic into a mold, which is like a special container that shapes things. Next, they blow air into the plastic, kind of like blowing up a balloon. This air pushes the plastic out to match the mold’s shape. Once it cools down, the plastic becomes solid in that shape. We see the results of blow molding in everyday items like water bottles, shampoo bottles, and even some toys!

What is the purpose of blow molding?

Blow molding is a super interesting process with a very specific purpose: to create hollow plastic items that we use in our daily lives. This method is super popular for several reasons, and it’s behind many items you probably use every day!

First off, blow molding is great for making bottles. Think of all the water bottles, soda bottles, and milk jugs in your fridge or pantry. This process makes all of these! The cool part? Blow molding can make bottles in all sorts of shapes and sizes. So, whether you need a small bottle for your salad dressing or a big one for laundry detergent, blow molding has got you covered.

But it’s not just about bottles. Blow molding also makes other hollow products, like fuel tanks in cars, containers for industrial products, and even toys. The process is super versatile, which means manufacturers can use it for a wide range of products.

Another key purpose of blow molding is to make products that are strong and durable. The items need to hold up well, whether they’re carrying liquids or enduring rough play from kids. Thanks to blow molding, these products can take a bit of a beating and still work great.

Eco-friendliness is another big reason why blow molding is popular. Many of the items made through this process are recyclable. So, when you’re done with that water bottle or detergent jug, you can recycle it, helping the environment.

Blow molding is also cost-effective, which is great for both manufacturers and consumers. It’s a relatively fast and efficient process, which means companies can make lots of products without spending too much time or money. These savings often get passed on to you, the consumer, making products more affordable.

Lastly, blow molding allows for customization. Manufacturers can easily tweak the process to create unique shapes and designs. This means they can make products that not only do their job well but also look cool or fit a specific need.

How to make blow mold?

Making a blow mold is a fascinating and intricate process that involves several steps. It’s how we get all sorts of hollow plastic products, from water bottles to automotive parts. Here’s a step-by-step guide to understanding how experts make a blow mold.

Step 1: Design the Mold

First, designers come up with a plan. They think about what the final product should look like and its size. They use computer software to create a detailed design of the mold. This design is super important because it determines the shape and features of the final product.

Step 2: Choose the Material

Next, they pick the right material for the mold. Most molds are made from metals like aluminum or steel. These materials are strong and can handle high temperatures, which is important for molding plastic.

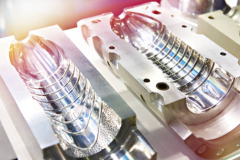

Step 3: Create the Mold

Now, it’s time to make the mold. This usually involves cutting the metal into the right shape. They use machines like CNC (Computer Numerical Control) mills that are really precise. The mold has two halves that fit together perfectly.

Step 4: Add Details

The mold makers then add details to the mold. This includes things like texture or logos. They also make sure there are channels for air and plastic to move through the mold.

Step 5: Prepare the Plastic

While the mold is getting ready, another team prepares the plastic. They choose the type of plastic based on what the final product needs to be like. They melt the plastic until it’s soft and gooey.

Step 6: Injection

The soft plastic gets injected into the mold. This is where the “blow” part comes in. They inject air into the mold, which blows up the plastic like a balloon. The plastic expands until it fills the mold.

Step 7: Cooling and Solidifying

After the plastic fills the mold, it needs to cool down. As it cools, it solidifies into the shape of the mold. This step is crucial because it’s when the product takes its final form.

Step 8: Open the Mold

Once the plastic is cool and hard, they open the mold. They have to be careful here to make sure the product doesn’t get damaged.

Step 9: Remove Excess Plastic

Sometimes, there’s extra plastic around the edges of the product. They trim this off to make the product look neat.

Step 10: Quality Check

Finally, they check the product to make sure it’s just right. They look for any flaws or issues. If it passes the check, it’s ready to go!

Step 11: Repeat

If they need more products, they repeat the whole process. This can be done pretty quickly, so they can make lots of products in a short time.

Bonus Step: Recycling

Sometimes, the excess plastic from the trimming process gets recycled. They melt it down and use it again, which is great for the environment.

Making a blow mold and using it to create plastic products is a mix of art and science. It involves careful planning, precise machinery, and a keen eye for detail. This process allows us to have all sorts of useful and neat plastic products in our daily lives!

Who makes blow molds?

Blow molds are made by skilled professionals working in specialized companies, and one such company worth mentioning is moldplasticinjection.com. They are experts in creating these intricate molds. The team there includes designers, engineers, and technicians, all working together. They use their skills and experience to turn ideas into real, tangible products.

Designers at moldplasticinjection the process. They use computer software to design the mold, thinking carefully about every detail. Then, engineers take over. They pick the right materials, usually metals like steel or aluminum, because these materials are strong and can handle heat well.

Next come the technicians. They use advanced machines to cut and shape the metal into the exact design. They pay close attention to every little detail, ensuring everything is perfect. This precision is super important for making high-quality blow molds.

After the mold is made, they test it to make sure it works just right. They check for any flaws and make adjustments if needed. Their goal is to make a mold that can create perfect plastic products every time.

So, if you’re looking for someone to make blow molds, the team at moldplasticinjection has the expertise and equipment to do a fantastic job. They combine art and science to make molds that meet all your needs.