The engineering plastics are getting more and more popular in modern automobile industry and auto parts producing with automotive molding process because of its characteristics of easy processing, good performance and low cost, it’s of great significant to replace steel products with automotive plastic injection molding services and plastic injection molded auto parts to realize automobile lightweight.

What is automotive molding?

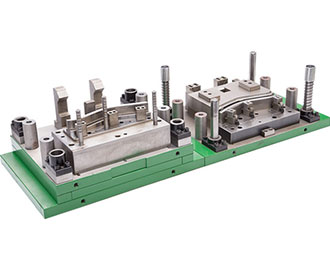

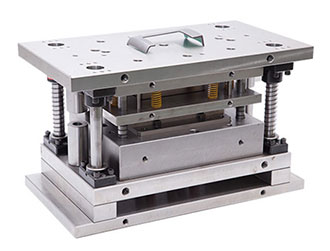

Automotive injection molding is the most widely used production methods in automotive plastic parts processing, refers to decorative and protective molding for car body, including side body molding, lower body molding, door molding, window molding, footrest molding, etc. the automobile dashboard, bumper, seat, and more products are adopt injection molding technology, especially the bumper molding, brings great solution for manufacturing quality and profitable plastic injection molded bumpers with high efficiency and excellent properties. Automobile molds are reliable to produce molded auto parts with high quality finish and mass production needs.

Plasticinjiectionmould.com can supply high-quality auto parts mold design and automotive plastic injection molded parts according to your requirements, you can find right car molding and automotive injection molding services to decorate and protect your car. Through years of experience in injection molding services and molds making, EX MOULD CO., LIMITED is your ideal partner to assist you in the automotive sector with high efficiency and strict quality control system. Our auto moldings feature car side molding, car door molding, car window molding, car molding trim, car roof molding, car bumper molding and others are made of PLA, ABS, PVC, Polycarbonate, etc., forming exterior and interior automobile components.

Center panel, Upper shell steer, Cradle Plate, Base door, Mirror cap, Main dash, Cover foot rest, Tray, Dash center part, Tank cac, Radiator hearder tank, Grille radiator, Belt cover, Drawer Rhd, Central consol, Wheel cap, Rear trunk panel, Post cover upper, Rear tail light, Trunk lining, Lining front look, fenders, door handles, etc.

- Services

- Materials

- Industries