Looking for plastic injection mold tooling services? PlasticInjiectionMould.Com get you covered with our design, engineering, and manufacturing services for Injection Moulds. EX Mold Technology Co. Ltd, the leading supplier and manufacturer of Injection Modes for Plastic Products in China, can offer the best service for plastic injection mold designing and making! On PlasticInjiectionMould.com, you can find the variety of Plastic Injection moulds, as we have the specialized injection mould designing team and skilled mold maker. Our Plastic Injection Moulds – the Injection Mold Tooling applied to produce plastic parts, can be designed and made to meet the needs of different industries.

Our Plastic Injection Moulds and Tools help you reduce the cost and reduce the labor intensity in terms of improving productivity and ensuring product quality. In terms of the below aspects, we have great advantages of our design for injection molding:

1.Our team of inject mold design engineers specializes in drawing with CAD, CAE, CAM, commonly using SOLIDWORKS, PRO ENGINEER, UNIGRAPHICS, and MOLD FLOW analysis software.

2.Adopting HASCO, DME, LKM standard, design processing paths with UG MANUFACTURING for making mold parts.

3.Comprehensive review of mold design drawings is a key step in the initial stage of plastic mould design. We try to find out the problems that may arise during mold design and solve them, determine the finally design of the plastic inject molds.

4.Advanced designing and manufacturing software simulates the entire process of plastic injection mold making and runs through all aspects of mold design, process development, machining, inspection, assembly, and molding.

5.Before a special processing and method planned for every custom injection molds, the mold drawings confirmed by the review are arranged by the mold technician.

6.The manufacturing and assembly of each part is carried out in the injection mold shop, and the designer works closely with the technical department.

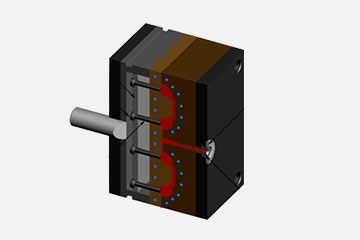

7.Multiple of plastic injection mold types – Cold Runner Mold, Hot Runner Mold, PVC mold, Insert Mold, Epoxy Mold are available to meet custom needs.

8.A variety of materials to choose from – hardened steel, pre-hardened steel, aluminum, and/or beryllium-copper alloy.

9.Design and manufacture the most cost-effective and high quality molds according to customer requirements.

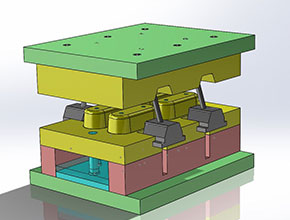

Injection molds, give plastic products complete structure and precise dimensions, refers to the tooling for producing a wide variety of parts. Plastic Injection Mould Designing and Making is has become an important part of modern industrial production, because many useful products in life and production, such as auto parts, toys, daily chemicals, kitchen utensils, electrical appliances, fashion accessories, and even military equipment, etc. are manufactured by using injection mold tooling.

Injection Molds are widely used, and the forming of product components in modern manufacturing requires almost all of them. Once a component’s mold is designed and made, plastic materials can be precision machined to form the features of the desired part. In the plastic injection designing process, it is necessary to comprehensively consider various factors to finally design the products to meet the production requirements. There are many factors to consider for injection molding design, but the part design and tool design are two of the most important. Getting injection mould design right could mean lower entry cost, high production quality, shorter cycle time, and quick assembly.

With the rapid development of the plastics industry, the requirements for plastic injection mold making are getting higher and higher. The success or failure of plastic processing not only depends to a large extent on the design effect of injection molds, but also the quality of injection mold manufacturing. A longer lifespan of Plastic Injection Moulds offset the higher initial cost over a higher number of parts made before wearing out, thereby save the total cost of produce plastic items with the injection mold tooling. Wide various of materials (typically constructed from hardened steel, pre-hardened steel, aluminum, and/or beryllium-copper alloy) and types of plastic injection molding systems (Cold Runner Mold, Hot Runner Mold, PVC mold, Insert Mold, Epoxy Mold) are used for Plastic Injection Mold making.

- Services

- Materials

- Industries