Professional plastic injection molding is often the 1st choice for manufacturing plastic parts these days. With multiple advantages like durability and enhanced efficiency attributed to the procedure, the decision is super easy.

But now that you have picked your manufacturing way, what are the key things to consider while choosing a professional plastic injection molding supplier to partner with?

Since plastic part manufacturing is a complicated procedure, it’s vital to consider some key factors while choosing a top-rated plastic injection molding supplier. Your ideal partner during the procedure should be able to suit your products and industry requirements.

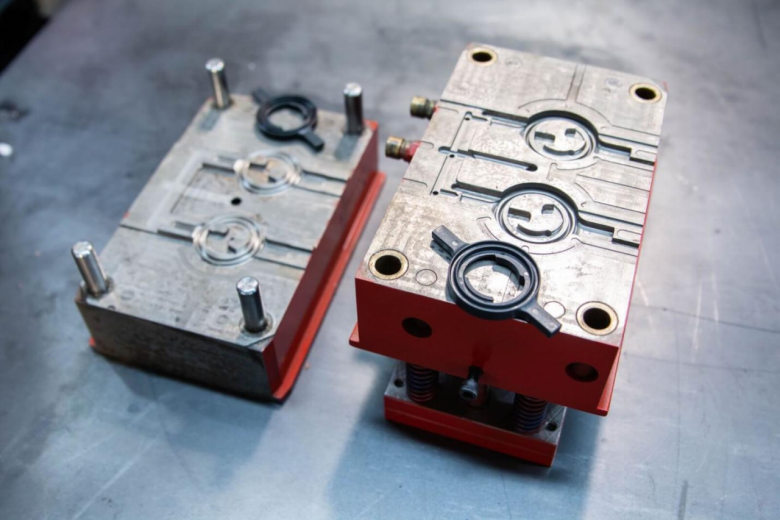

To start with getting a fine understanding of the plastic molding procedure. In simple terms, the procedure uses plastic polymers that are melted and injected into a custom injection mould design under high pressure.

Sounds simple? I think not really!!!

The procedure has several minute details and steps that need to be followed to make complex plastic parts. This is the key reason why manufacturers often look for a plastic injection molding supplier that creates to their needs and budget constraints.

Following are the key factors that you have to consider while choosing a plastic injection mold maker

Wide Range of Services

Irrespective of the type & volume of plastic parts that you need, it’s vital to consider a plastic injection molding maker that provides a one-stop manufacturing solution. Injection molding suppliers who also provide early level consultation, starting from the design and concept stage of the part can help make optimal designs that meet your budget needs.

When considering a professional plastic molding manufacturer, think of the expanded service and technical needs during the manufacturing procedure. Choosing a company that offers a wide range of services- part design, prototype and mold flow analysis, etc moreover to the usual services is suggested.

Great design team

Design is vital aspects of the plastic molded part. Choosing a custom molding injection maker that has a great design team will go a long way in ensuring the desired outcomes. Starting with clear design concepts is key to making sure that the production procedure gets on efficiently.

An experienced team should be able to simplify the design of the part to minimize the numbers. This is a key step in deciding the overall budget to increase the return on investments.

Production Capacity and Volume

It’s vital to narrow down your selection of a plastic injection molding supplier by considering the size and volume of your production requirements. Various suppliers specialize in different capacities. Low to moderate capacity suppliers will be able to provide you with the production of thousands of parts.

Low to moderate volume produces are wonderful for considering this range of volume or looking to make a prototype for testing. Various applications are not required to be produced in high volumes. A low-moderate ranging molding supplier like Mold Plastic Injection is ideal for such orders.

Plastic Injection molding is a top choice when it comes to manufacturing plastic parts. By considering these top factors, you can streamline the procedure of choosing a plastic injection molding maker that suits your needs.[/caption]

Product Application

Another factor to consider when selecting a PVC injection molding supplier is the product application. The intended use of parts is key when considering various manufacturing stages like development, design, and production.

An injection molding supplier should be able to guide you in picking the right type of resin for different product applications. Different resins have different properties in terms of flexibility, strength, durability, and heat resistance. Plastic is not being used in many industries as a substitute for metal to decrease weight and minimize cost.

Your chosen plastic molding supplier should guide you on the right PVC resin based on the product’s end use and your budget.

Quality Assurance

In addition to the consideration like specification and technology, it’s vital that chosen company is well established and has an in-home quality assurance team to monitor the procedure. While this factor is often ignored, it’s extremely vital in ensuring that you get the right services.

The plastic market is extremely competitive. Choosing a supplier that can give quality assured products and is committed to offering efficient services is important.

Check whether your chosen partner has high quality machines to carry out the project. Further, make sure that the company is recognized in the industry. Doing a fast background check on the reviews and performance awards achieved by the professional plastic injection molding supplier is suggested.

Wrap up…

Accounting for each mentioned factors helps you in choosing a reliable and professional plastic injection molding company. Careful planning and survey during the projection inspection phase will help you streamline the procedure of choosing a company that understands your needs. Mold Plastic Injection are leading plastic injecting molding supplier in the industry, we provide a range of services for many industries with huge experience. If you’re looking for a top-rated plastic injection molding supplier, don’t go anywhere, EX MOULD Co. is here for you.