2022.9.22

Injection moulding is a process for creating parts and products from various plastic materials. It works by injecting molten plastic into a mould, where it cools and hardens to the shape of the mould. The injection moulding machine process is a versatile manufacturing method that can be used to create a wide variety of parts and products, from simple to complex.

Injection moulding is a popular manufacturing choice for many reasons. It is relatively quick and easy and can be used to create parts with high accuracy. The injection moulding process is also versatile, as it is possible to utilize it to make pieces with a variety of sizes, shapes, and material characteristics. Plastic injection moulding is very versatile, making it well-suited for mass production.

If you are considering injection moulding for your next manufacturing project, be sure to work with a reputable and experienced company. Injection moulding is a complex process, and working with good tools is necessary. EX MOULD Co. Ltd. has over a decade of experience focusing on Complex Mold Construction. We have a high-tech company that specializes in precision plastic mould design, manufacturing, injection moulding, spraying, and other one-stop services. Here you can get an injection moulding tool of the best quality.

An injection moulding machine does injection moulding. An injection moulding machine is a piece of equipment that uses high pressure and temperature to create solid plastic parts or objects. It is an important manufacturing process in the production of many products, such as toys, electrical devices and other stuff.

Injection moulding machines use high temperatures and pressure to create parts, which can pose fire hazards if you don’t use them the right way. The machine should always be kept away from flammable materials. Additionally, they should be maintained regularly to ensure they are working properly.

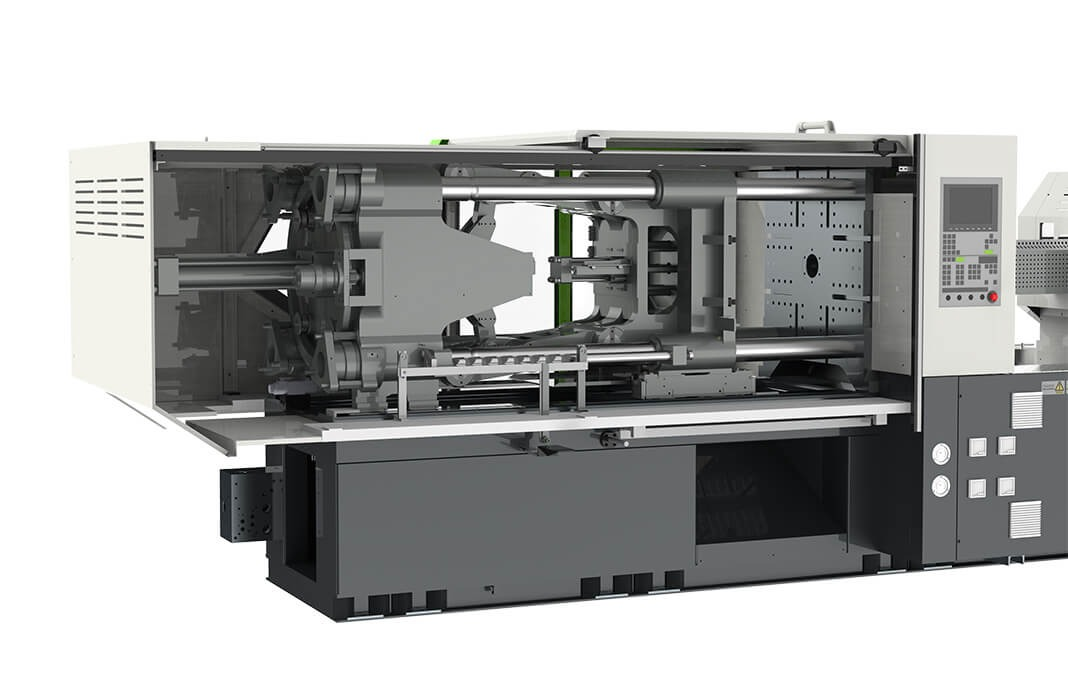

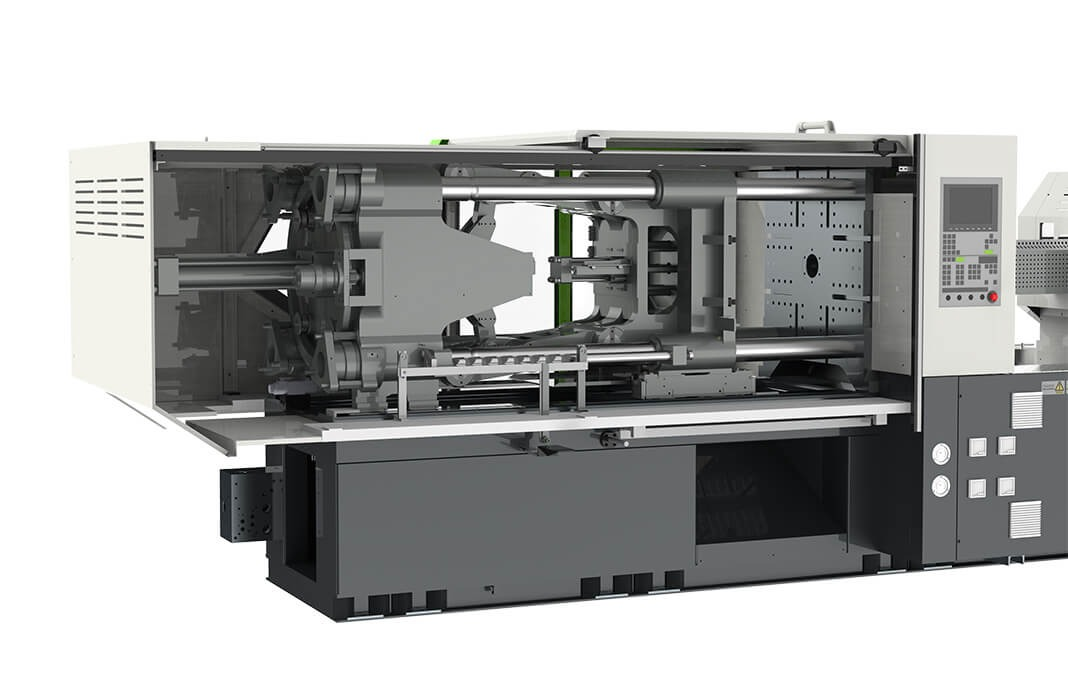

Injection moulding machines are complex pieces of machinery consisting of several different components. Each component plays an important role in the overall function of the machine.

The injection unit is the part of the machine that melts the plastic and injects it into the mould. The clamping unit is the part of the machine that holds the mould in place and opens and closes it. And control unit is the part of the machine that controls the injection and clamping units. It also monitors the process and makes sure that the machine is operating correctly.

These are the main components of an injection moulding machine. Each one is essential to the proper functioning of the machine.

The process begins with a mould, which is an impression of the desired product. The mould is then filled with plastic or metal, which is injected into the mould under high pressure. Clamping injection moulding is a type of injection moulding process in which the injected plastic material is held together. We use it to produce more complex parts with more precise geometry.

In order to ensure that the plastic is evenly distributed and cooled down during production, cooling channels are typically added to the injection head. Cooling channels direct the hot plastic from the injection head to coolers, where it is further cooled before being moved to another part of the line for further processing.

The ejection step is the process of removing the moulded product from the mould. You want to consider a few things when doing this step in the injection moulding process. These include the type of material being used, the size and shape of the mould, the depth of the mould, and the speed of the injection process. The ejection step must be designed to ensure that the product is ejected from the mould without damaging it.

It is easy to learn how to operate an injection moulding machine. However, there are a few things you should keep in mind before you carry injection molding process steps at home:

1. Variable temperatures must be controlled during the injection process to ensure even cooling throughout the material’s cross-section.

2. Set the right temperature throughout the cycle. Otherwise, the plastic will cool too quickly and cause final product quality problems.

3. For long-term reliability, always use high-quality components when assembling your machine.

Injection moulding is a machine process to form plastic parts in precisely controlled conditions. Injection moulding typically involves the injection of molten thermoplastic into a mould, which cools and solidifies around the part. The finished piece can then be removed from the mould and often further processed – for example, by cutting or machining it – before it is ready for sale. Injection moulding can be used to produce a wide range of products, including toys, food containers, medical devices like artificial knee implants, and more.