As one of the pillar industries of China’s light industry, the growth rate of plastic industry has been maintained at more than 10% in recent years. In the plastic industry, the market of plastic hardware industry is very active and has become a new consumption hotspot and a new economic growth point. The market prospect of plastic mould is considerable, but it is far from the technical level of foreign countries.

At present, China’s mold industry needs to break through the bottleneck restricting the development of the mold industry.

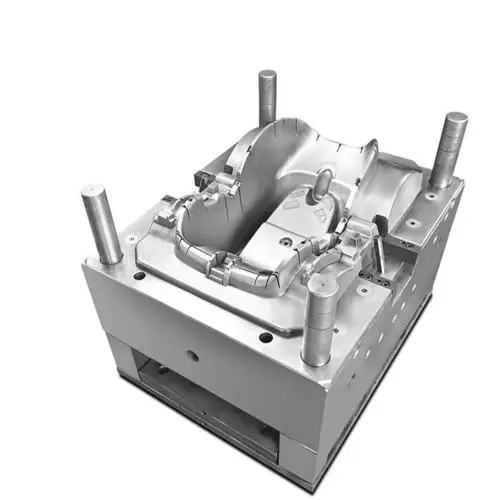

Because with the rapid development of China’s pillar industries such as machinery, automobile, household appliances and building materials, plastic molds account for about 30% of the whole mold industry. However, due to the complex shape of plastic mold accessories, there are high requirements for their design level. Therefore, the technical level of mold test result inspection must be innovated to keep up with the development trend of the times, otherwise the development of plastic mold will be restricted.

The industry believes that plastic mold manufacturing enterprises must improve their own technology if they want to break through the bottleneck. At the meeting of the State Council on October 26, 2015, the premier also said that today’s technological revolution plays an extremely key role in economic development and promoting economic upgrading. Advocating mass entrepreneurship and innovation is also to promote entrepreneurship by innovative means.

The foreign trade deficit of mould has increased year by year. Although the growth rate of mould export is greater than that of import in recent years, the absolute amount of increase is still greater than that of export, resulting in the increase of mould foreign trade deficit year by year. This situation has improved in 2006, with a slight reduction in the deficit. There are two main reasons for the increase of the foreign trade deficit of molds: first, the sustained and rapid development of the national economy, especially the rapid development of the automobile industry, has brought about a strong demand for molds. Some high-grade molds can not be produced at home, so they have to be imported; But there are some molds that can be produced in China and are also being imported. This is related to China’s current tariff policy and project approval system. Second, the encouragement of mold export is not enough. Now, like other mechanical and electrical products, the export tax rebate rate is only 13%, but not 17%.

According to the forecast report on the development prospect of China’s plastic mold industry, plastic mold manufacturers should focus on developing large, precision, complex and long-life molds with high technical content, vigorously develop the international market and export molds.

With the rapid development of China’s plastic industry, especially engineering plastics, it can be predicted that the development speed of China’s plastic mould will continue to be higher than the overall development speed of the mould industry, and the annual growth rate will remain at about 20% in the next few years.

New trend of plastic mold development in the four elements of mold quality, delivery cycle, price and service, more and more users have put the delivery cycle first.

It has become a trend to require mold companies to deliver as soon as possible. Enterprises try their best to improve their adaptability, technical level, equipment level, management level and efficiency are effective means to shorten the mold production cycle.

Vigorously improve the development ability, push the development work forward as far as possible until it is involved in the product development of mold users, and even carry out the development before there is no clear user object, so as to change from passive to active.

At present, this method has been adopted for TV and display shell, air conditioner shell and motorcycle plastic parts, and the development of mobile phone and telephone mold has also begun to try. This practice breaks the passive situation that the mold factory can only wait for the contract to design the mold according to the user’s requirements for a long time.