14

2023.6

How Does a Blow Molding Machine Work: An In-Depth Guide

Introduction A common manufacturing method that enables the creation of hollow plastic objects in a variety of shapes and sizes is blow molding. The purpose of this essay is to provide readers a thorough grasp of how a blow molding machine operates. We will examine the various types of blow molding equipment, the detailed procedure involved, and the advantages of this ground-breaking technology. So let us dive in and see how a blow molding machine operates from......

9

2023.6

Got a Sink Mark Defect? Here’s What You Can Do

Have you ever seen sink marks on your plastic parts after the molding process? Sink marks occur when the material in the plastic cools and shrinks faster than the surrounding area, causing a visible indentation on the surface of the part. Sink marks are a common problem in plastic injection molding and can be caused by a variety of factors, such as uneven wall thickness, improper cooling, or insufficient packing pressure. But don’t worry, there are sev......

6

2023.6

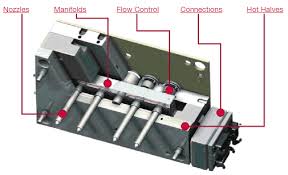

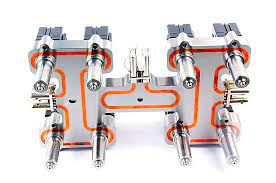

8 Key Advantages of Hot Runner Systems – Part 2

Welcome to the second part of our blog series on the many advantages of hot runner systems. If you missed Part 1, don’t worry; we won’t hold it against you. Key advantage 4: Minimal material wastage To reduce material wastage during the manufacturing process, hot runner systems offer a cost-effective solution. By eliminating cold runner scrap, these systems minimize material waste and provide better control over mold filling, resulting in higher......

4

2023.6

8 Key Advantages of Hot Runner Systems – Part 1

Are you looking for ways to improve your mold making process? Hot runner systems might just be the solution you’re looking for. These systems are designed to optimize the injection molding process by eliminating the need for runners, making it more efficient and cost-effective. In this blog, we will discuss what hot runner systems are, their purpose in a mold, and the key advantages they offer. From reduced cycle time to improved part quality, and minimal ma......

3

2023.6

When it comes to choosing the right material for your project, there are many factors to consider. Two commonly used materials in manufacturing are PA66 and PA6. Both are thermoplastics that offer high strength and durability, but there are some key differences between them. We will explore what PA66 and PA6 are, their chemical and physical properties, and the advantages and disadvantages of each. We will also discuss the injection molding process for both materia......