10

2023.5

Nylon Pa6 and Pa66 Differences in the Plastic and Rubber Industry

If you are in the plastic and rubber industry, you would have come across Polyamide (PA) or Nylon as it’s commonly known. PA6 and PA66 are two types of nylon materials that are widely used in the industry. Though they may seem similar, they have distinct differences that can significantly impact their application. Here we look at what PA6 and PA66 materials are, their key differences, and how they differ structurally and physically. We will also explore proc......

9

2023.5

How to set your Injection Molding Machine Parameters?

Injection molding is a complex process that requires expertise and precision. The success of the process depends on several factors, including the machine parameters. Setting up the injection molding machine parameters can be a daunting task, especially for beginners. In this blog, we will guide you through the process of setting your injection molding machine parameters. We will cover everything from understanding the key parameters for injection molding to tips ......

7

2023.5

A Close Look at PA6 and PA66 Properties – Part 2

A Close Look at PA6 and PA66 Properties – Part 2 In our previous article, we discussed the properties and applications of PA6 and PA66. In this installment, we will delve deeper into their mechanical properties.PA6 has a higher impact resistance than PA66, which makes it a better choice for parts that need to withstand sudden shock loads. On the other hand, PA66 has a higher modulus of elasticity, making it stiffer and more suitable for parts that require hi......

6

2023.5

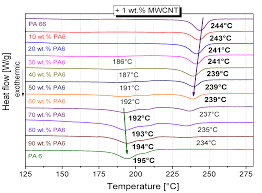

A Close Look at PA6 vs PA66 Properties – Part 1

Polyamides or nylon is a widely used synthetic polymer with applications ranging from textiles to engineering plastics. Among the different types of polyamides, PA6 and PA66 are the most commonly used ones in the industry. But how do they differ from each other? In this blog, we will provide an in-depth analysis of the properties of PA6 vs PA66. We will discuss their molecular and physical structures, as well as process conditions related to their manufacturing. A......

5

2023.5

Process Conditions for PA6 and PA66

Did you know that the right processing conditions can impact everything from part performance to production efficiency? That’s right; it’s not just about melting some plastic and hoping for the best. In this blog post, we’ll dive into the nitty-gritty details of what makes the perfect Process Conditions for PA6 and PA66 for these two types of nylon. We’ll cover everything from temperature and pressure to screw speed and cooling time –......