22

2024.12

What are the Benefits of our Bumper Moulding Service

Bumper molding is an essential part of custom car bumper production and protection. A well-crafted bumper guarantees safety, durability, and a complicated search for any automobile. At EX MOULD Co., we specialize in presenting the best bumper molding services. Whether you’re an automaker or want alternative bumpers, we offer cost-effective, excellent solutions tailored to your wishes. With over 10 years of experience, our expert group guarantees the best res......

22

2024.12

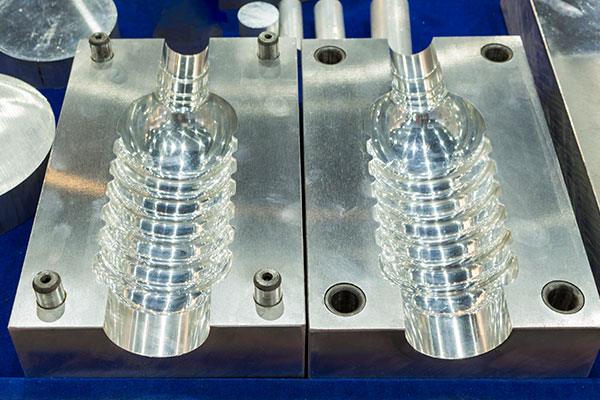

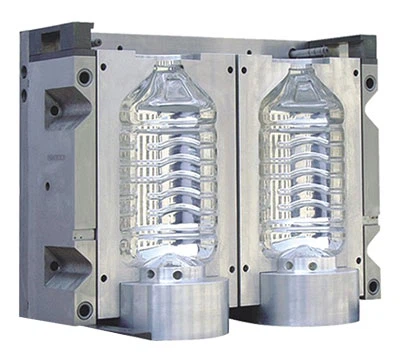

Which Blow Molding Process is Right for Your Bottle

4 essential blow Molding Process form heated plastic into hole objects like bottles or boxes. These techniques use air strain to force the melted plastic into molds, offering the bottle its shape. At EX MOULD Co., we employ all 4 methods to supply excellent bottles: Extrusion Blow Molding (EBM), Compression Blow Molding (CBM), Injection Blow Molding (IBM), and Injection Stretch Blow Molding (ISBM).Choosing the right gadget depends on elements like the size and sha......

18

2024.12

Choosing the Right Injection Mold for Scalable Manufacturing

When it comes to manufacturing at scale, injection molding is the go-to process for creating high-quality, repeatable parts with remarkable efficiency. But the unsung hero of the process? The mold itself. Choosing the right injection mold can make or break your project — impacting everything from production speed to part consistency and overall cost. So how do you pick the right mold? It ‘ s not just about material or size; it ‘ s about aligning your......

18

2024.12

From Prototype to Production: How Injection Molds Drive Efficiency

Turning a great idea into a successful product is no small feat. From the initial sketches on paper to seeing your creation on store shelves, the journey can feel like a marathon. But one crucial step can significantly streamline this process:injection molding. Often overlooked as just a manufacturing technique, injection molding is actually a game-changer, bridging the gap between a concept and a cost-effective, high-quality product. This article explores how i......

18

2024.12

What Is the Best Plastic Material for Injection Molding

Injection molding is one of the most versatile and widely used manufacturing processes for producing plastic components. However, choosing the right plastic material is critical to achieving optimal performance, cost-efficiency, and durability. With a vast array of plastics available, each suited to specific applications, it’s essential to understand the properties, advantages, and limitations of different options. In this blog, we’ll explore some of the most comm......