Plastic injection molding is a widely used manufacturing process for creating plastic parts and products. Whether you’re a fashioner, engineer, or curious about how everything functions, this article will dig into the fundamental inquiries connected with plastic injection molding. Let’s explore the Plastic Injection Molding Process: Top Questions & Answers.

Plastic Injection Molding Process: Top Questions & Answers

What Is Plastic Injection Molding?

Answer: In plastic injection molding, the star entertainer is made of liquid plastic. This is the carefully guarded secret:

- Casting the Mold: Consider moulding the stage. It’s a specially crafted depression, carefully intended to make the ideal plastic part. The mold resembles a guide’s rod, directing the exhibition.

- The Dance of Plastic: Liquid plastic pirouettes into the mold under high tension. It fills everywhere, catching many subtleties. The mold murmurs, “mold up!”

- Cooling and Hardening: The spotlight moves to cooling. The mold cools the plastic, freezing it into its last structure. The crowd (that is us!) holds up in expectation.

- Curtain Call: The mold opens, and presto! The plastic part arises, prepared for its job in our day-to-day routines.

How Does the Injection Molding Machine Work?

Answer: Picture a backstage crew working tirelessly behind the scenes. The injection molding machine is our backstage hero. Here’s its choreography:

- Hopper: The hopper holds plastic pellets, like eager dancers waiting for their cue.

- Barrel and Screw: The screw twirls, melting the plastic. It’s the prima ballerina, graceful and precise.

- Nozzle: The nozzle connects the barrel to the mold. It’s the bridge between backstage and center stage.

- Clamping Unit: The clamping unit holds the mold shut during the performance.

- Injection Unit: This unit injects molten plastic into the mold. Applause!

What Types of Plastics Can Be Used?

Answer: Our plastic ensemble includes stars like:

- Polypropylene (PP): Lightweight and versatile, like a prima donna who can play any role.

- Acrylonitrile Butadiene Styrene (ABS): Durable and impact-resistant—our action hero.

- Polycarbonate (PC): Transparent and strong, perfect for show-stopping moments.

- Polyethylene (PE): The reliable supporting actor, used for packaging and containers.

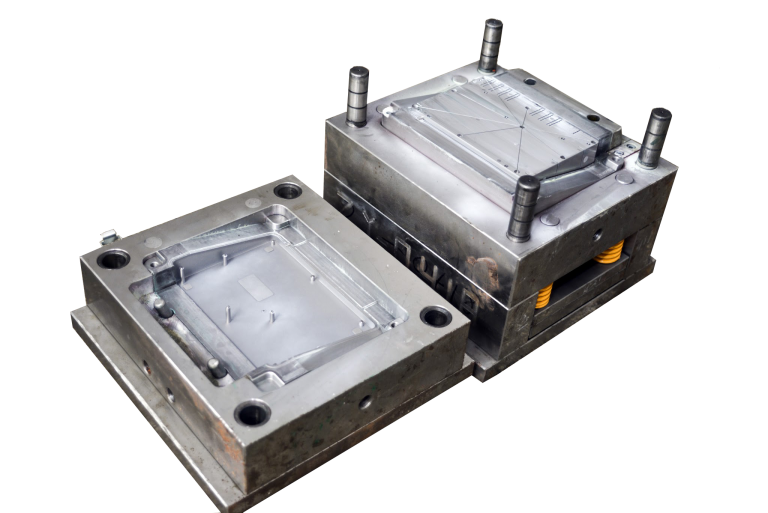

What Is the Mold Design Process?

Answer: Mold design is like composing a symphony:

- Part Design: Imagine a composer sketching musical notes. We create a 3D model of the plastic part.

- Gate Placement: The conductor decides where the plastic enters the mold—like choosing the right tempo.

- Runner System: Channels distribute plastic within the mold, harmonizing flow.

- Cooling System: Like tuning instruments, we ensure uniform cooling to prevent warping.

- Ejection System: The grand finale—the part gracefully exits the mold.

How Is Injection Pressure Controlled?

Answer: Injection pressure affects part quality. It’s controlled by adjusting:

- Injection Speed: Faster for thin walls, slower for thicker sections.

- Injection Pressure: Higher pressure for complex shapes.

- Holding Pressure: Maintains pressure during cooling.

What Are Common Defects in Injection Molding?

Answer: Common defects include:

- Flash: Excess material at parting lines.

- Sink Marks: Indentations due to uneven cooling.

- Warping: Distortion caused by uneven shrinkage.

- Short Shots: Incomplete filling of the mold.

How Is Cooling Managed?

Answer: Proper cooling is crucial. Cooling channels in the mold dissipate heat. Uniform cooling prevents warping and ensures consistent part dimensions.

What Is Overmolding?

Answer: Overmolding involves adding a second layer of plastic onto an existing part. It’s used for soft grips, multi-color parts, or combining different materials.

What Is the Role of the Draft Angle?

Answer: Draft angles allow easy ejection of the part from the mold. A slight taper prevents sticking.

How Can I Optimize Injection Molding for Cost Efficiency?

Answer: Consider:

- Material Selection: Choose cost-effective materials.

- Design Simplicity: Minimize complex features.

- Tooling Optimization: Efficient molds reduce production costs.

Your Premier Plastic Injection Mold Manufacturer in China

Regarding plastic injection molds, EX MOULD Co., LIMITED Ltd stands apart as a top-grade producer. We should dive into for what reason they’re the go-to decision for organizations around the world.

Experience and Mastery: With north of 10 years of involvement, EX MOULD has sharpened its art. Their gifted group of configuration architects, engineers, and skilled workers guarantees accuracy and quality in each shape they make.

Comprehensive Services: EX mould covers the whole range, from counselling and planning to prototyping and creation. Whether you want a solitary model or mass volume forming, they take care of you.

Extensive variety of Materials: They work with a variety of ensured materials — PLA, ABS, Nylon, PVC, Carbon Fiber, and that’s only the tip of the iceberg. Anything your task requests, EX Form can convey.

Variety of Molds: EX MOULD creates different shape types, including Hot Sprinter, Cold Sprinter, Supplement, Epoxy, Silicone, and Blow molds. Their adaptability guarantees your remarkable prerequisites are met.

Quality Confirmation: They ensure 100 per cent quality in their injection molds. Their obligation to craftsmanship and scrupulousness put them aside.

Final Words

In summary, plastic injection molding consolidates science, craftsmanship, and design to make regular articles we frequently underestimate. Understanding its subtleties enables us to configure better items and value the enchanted behind plastic assembling.