In recent years, with the rapid development of the plastic industry and the continuous improvement of the strength and precision of general and engineering plastics, the application scope of plastic products is also expanding. A reasonably designed plastic part can often replace many traditional metal parts. Why plastic mold products are popular now, the reason you are about to find out. This article is going to show you everything about the manufacturing process, design, definition and composition of plastic injection molds.

What Is Plastic Injection Mold?

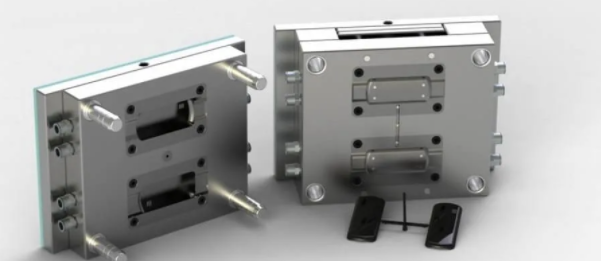

Plastic mold is a tool for the plastic manufacturing industry and plastic forming machine, which endows plastic products with complete configuration and precise size. Due to the variety of plastics and processing methods, the structure of plastic molding machines and plastic products is complex and simple, so the type and structure of plastic mold is also diverse.

Plastic is a kind of material with polymer synthetic resin as the main component, plasticity and fluidity under certain temperature and pressure, which can be molded into a certain shape and keep the shape unchanged under certain conditions. Plastic is composed by polymer synthetic resin (40 ~ 100%)

It has supplementary materials: plasticizer, filler, stabilizer, lubricant, colorant, foaming agent, reinforcing material. Auxiliary material function: improve the material performance and processing performance, save resin material.

Classification Of Plastics

There are more than 300 kinds of plastics, and more than 40 kinds are commonly used. The name is based on the name of synthetic resin used: polyethylene, polypropylene, polyvinyl chloride, phenolic resin, oxygen resin, commonly known as: Bakelite (phenolic resin), plexiglass (polymethylmethacrylate), glass fiber reinforced plastics (thermosetting resin), glass fiber reinforced, nylon (polyamide) Pa, polyethylene PE. The classification of plastics as follows:

Thermoplastic: with linear molecular chain into a scaffold structure, heating soft, cold but irreversible curing. Thermosetting plastics and thermoplastics (according to the molecular structure of plastics)

Thermosetting plastics: with network molecular chain structure, heat softening, irreversible after curing

General plastic: refers to the production of large, wide range of uses. A kind of cheap plastic. Such as: polyethylene, polypropylene, polyvinyl chloride, polystyrene, aldehyde phenol plastic, amino plastic accounted for 60% of plastic production

Engineering Plastics: refers to a kind of engineering materials with high mechanical properties, which can replace metal, such as nylon, polyphosphate, polyoxymethylene, ABS

Special plastic: oxygen gap resin

The Advantage of Plastics

1. Light weight, density 0.9~0.23g /cm^ foam 0.189g/cm

2. High specific strength: 1 / 10 of the strength of metal materials. FRP has higher strength and good chemical stability

4. Excellent electrical insulation performance

5. Good insulation

6. It is easier to form and process than metal

7. Deficiency: the strength and rigidity are not as good as metal, and are not heat-resistant. Under 100C, the coefficient of thermal expansion is large, easy to creep and aging.

How Does Plastic Injection Molding Work

The thermoplastic injection molding process has hygroscopicity: water absorbent (ABS, nylon, PMMA) and water-absorbent (polyethylene) have high water content, easy to foam and need to be dried. Plastics mold making have different states:

Glass state (general plastic state, TG higher than room temperature) The second: High elastic state (the temperature quotient is TG, and the polymer becomes soft and elastic like rubber) The third one: Viscous flow state (above the dip fluidization temperature, the plastic fluidity and viscous liquid flow zone of polymer appear one after another, and the plastic molding process is introduced in the viscous flow state of material)

Liquidity: Plastic in a certain temperature and pressure, can fully fill the mold cavity of each part of the performance, called fluidity. The fluidity is poor, so the injection molding needs more pressure; if the fluidity is too good, it is easy to salivate and cause an overflow.

Rheology: The properties of high polymers that produce fluidity and deformation under external action are called rheology. Newtonian fluid and non-Newtonian fluid. Most polymer melts behave as non-Newtonian fluids during the molding process. Newtonian fluid: mainly depends on (flow deformation is) shear stress, shear rate and absolute viscosity. Liquid or solution fluid of low molecular compound belongs to Newtonian fluid.

Crystallinity: whether it can crystallize during condensation. Amorphous plastics and crystalline plastics.

Crystalline: nylon, polypropylene, polyethylene, amorphous plastic: ABS

Heat sensitivity and water sensitivity

Phase fusibility: if two kinds of plastics can be fused together, if not, they will be layered and peeled.

Stress cracking and melt cracking

Thermal performance and cooling rate

Molecular orientation

Contractility

Toxicity, irritation and corrosiveness

Design Principles Of Plastic Injection Molds

The dimensions of plastic mold making products mainly meet the use requirements and installation requirements. At the same time, the processing and manufacturing of the plastic mold, the performance of the equipment and the fluidity of the plastic should be considered. There are many influencing factors, such as mold manufacturing accuracy, plastic mold making composition and process conditions. It is determined by the surface roughness of the mold, so the surface roughness of the mold is generally one level lower than that of the product.

The plastic mold surface should be ground and polished, and the surface finish of the mold cavity and the core should be consistent through the product. If there is no tolerance requirement on the plastic part ring, it is still determined by the size. Generally, 8 in the standard is used The dimension of the hole can be marked with positive tolerance, while the dimension of shaft can be marked with negative tolerance. The center distance dimension can meet the positive and negative tolerance, and the dimension of fit part is higher than that of non fit part.

Demoulding Slope Of Plastic Molds

Due to the cooling shrinkage of the plastic mold parts in the cavity, the plastic parts cling to the core and the protruding part of the mold cavity, which makes it difficult to take out the plastic injection mold parts. Forced removal will lead to the surface friction and galling of the plastic parts. In order to facilitate the demoulding, the inner and outer surfaces parallel to the direction of demoulding (and shaft core) must be considered in the design of the plastic parts, and enough demoulding slope, generally 1 ° to 1 ° 30 ‘.

Generally, the inclination of the core is larger than that of the cavity. The larger the length of the core and the depth of the cavity, the inclination will not decrease.

According to the use requirements of plastic mold parts (strength and stiffness), the structural characteristics of products and the requirements of mold forming process, the wall thickness is too small, the strength and stiffness are insufficient, and the plastic filling is difficult.

If the wall thickness is too large, the cooling time will be increased, the productivity will be reduced, bubbles and shrinkage will be produced. It is required that the wall thickness should be uniform as far as possible, otherwise the internal stress will be generated easily due to the different cooling and curing rates, which will cause the deformation and cracking of the plastic parts.

First, the middle stiffener should be more than 0.5 mm lower than the outer wall to make the bearing surface easy to be straight. Then, th local accumulation of plastic mold should be avoided or reduced. Last, the arrangement of ribs should follow the flow direction in the cavity.