Plastic objects are found everywhere in our daily lives, they are being used to make everything from electronic parts to automotive parts. Each application requires a special manufacturing process that can mold the part based on specifications. There are many types of plastic molding processes such as rotational molding, injection molding, thermoforming, vacuum, casting, etc. This guide presents the top 8 plastic forming processes, and we’ll explain all these characteristics, pros & cons, applications to help you discover the ideal process for your product.

8 Common Plastic Forming Processes – Characteristics, Pros & Cons, Applications

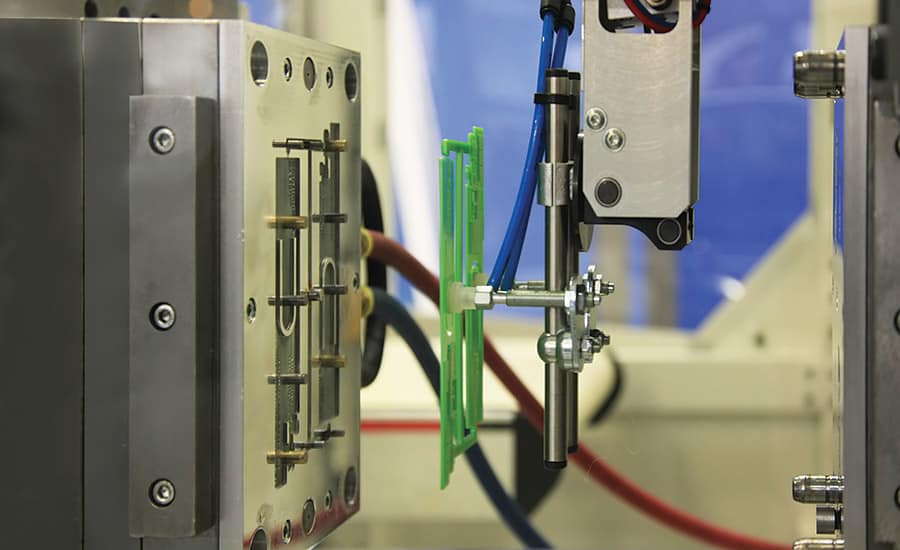

1. Injection Molding

Its principle is to add granular or powdery raw materials into the hopper of the injection machine, the raw materials are heated and melted into a flowing state, pushed by the screw or piston of the injection machine, enter the mold cavity through the nozzle and the mold pouring system, and harden and finalize in the mold cavity. Factors affecting the quality of injection molding: injection pressure, injection time, injection temperature.

Characteristics:

Advantages

– Short molding cycle, high production efficiency, easy to realize automation

– Plastic parts with complex shape, accurate size and metal or non-metal inserts

– Stable product quality

– Wide range of adaptation

Disadvantages

– High price of injection mold equipment

– Complex structure of injection mold

– High production cost, long production cycle, not suitable for single piece and small batch production of plastic parts

Application

Among the industrial products, injection molding products include: kitchen supplies (garbage cans, bowls, buckets, kettles, tableware and various containers), shells of electrical equipment (hair dryer, vacuum cleaner, food mixer, etc.), toys and games, various products of the automobile industry, and parts of many other products.

2. Insert Molding

Insert molding refers to the molding process of putting prepared inserts of different materials into the mold and then injecting resin. The melted materials and the inserts are joined and solidified to make an integrated product.

Characteristics

- ● The combination of resin’s easy formability, bending and metal’s rigidity, strength and heat resistance can be used to make complex and delicate metal plastic integrated products.

- ● In particular, the combination of resin insulation and metal conductivity can meet the basic functions of electrical products.

- ● For the rigid molding products and the bending elastic molding products on the rubber sealing plate, the complex operation of arranging the sealing rings can be avoided after the integrated products are made by injection molding on the base, which makes the automatic combination of the subsequent processes easier.

- ● The pre forming combination of multiple inserts makes the post engineering of product unit combination more reasonable.

3. Two Color Injection Molding

Two color injection molding is a molding method for injecting plastic with different colors into the same mold. It can make the plastic appear two different colors, and can make the plastic parts present regular patterns or irregular moire patterns, so as to improve the usability and aesthetics of the plastic parts.

Process Characteristics

● The core material can use low viscosity material to reduce the injection pressure.

● In consideration of environmental protection, the recycled secondary materials can be used as the core materials.

● According to different use characteristics, for example, soft material is used for thick finished leather material, hard material is used for core material or foamed plastic can be used for core material to reduce weight.

● Lower quality core materials can be used to reduce costs.

● Coating material or core material can be used with high price and special surface properties, such as anti electromagnetic interference, high conductivity and other materials to increase product performance.

● The proper mixture of the core material and the cortex material can reduce the residual stress of the products, increase the mechanical strength or the surface properties of the products.

4. Blow Molding

Blow molding is a method of making hollow, thin-walled, custom plastic parts. Clamp the melt thermoplastic raw material extruded from the extruder into the mold, then blow air into the raw material, the melted raw material expands under the action of air pressure, fits to the mold cavity wall, and finally cools and solidifies into the required product shape.

Common Uses for Blow Molding

Blow molding processes generate, in most cases, bottles, plastic drums, and fuel tanks. If you need to make a lot of bottles, this process is perfect for you. Blow molding creates very uniform, thin walled containers and in an economically way.

5. Extrusion Molding

It’s mainly suitable for the molding of thermoplastics, and also for the molding of some thermosetting and reinforced plastics with better fluidity. The forming process is to use the rotating screw to extrude the thermoplastic raw materials which are heated and melted from the head with the required cross-section shape, and then set them by the finalizer, and then make them harden and solidify through the cooler to become the products with the required cross-section.

Process Characteristics:

● Low equipment cost

● Simple operation, easy process control and continuous automatic production

● High production efficiency, uniform and dense product quality

● By changing the die, the products or semi-finished products with various section shapes can be formed

Application:

In the field of product design, extrusion molding has a strong applicability. Extrusion molded products include pipe, film, bar, monofilament, flat belt, net, hollow container, window, door frame, plate, cable cladding, monofilament and other profiles.

6. Rotational Molding

This process is to add the plastic raw materials into the mold first, and then the mold rotates and heats along the two vertical axes, so that the plastic raw materials in the mold can be coated and fused and adhered to the whole surface of the mold cavity gradually under the action of gravity and heat energy, forming into the required shape, then cooling, setting and demoulding, and finally obtaining the products.

Advantages:

– Provide more design space and reduce assembly cost

– Simple change and low cost

– Save raw materials

Application:

Water polo, floating ball, small swimming pool, bicycle cushion, surfboard, machine shell, protective cover, lampshade, agricultural sprayer, furniture, canoe, camping vehicle roof and so on.

7. Compression Molding

Compression molding is the main method of molding thermosetting plastics and reinforced plastics. The technological process is to pressurize the raw materials in the mold heated to the specified temperature, so that the raw materials melt and flow and fill the mold cavity evenly. After a certain period of time under the conditions of heating and pressurization, the raw materials form products.

Process Characteristics:

Compression molded products are compact in texture, precise in size, smooth in appearance, without gate marks and good in stability.

Application:

Among the industrial products, the compression molded products include electrical equipment (plug and socket), pot handle, handle of tableware, bottle cap, toilet, non broken dinner plate (Meinai dish), carved plastic door, etc.

8. Microcellular Foam Injection Molding Process

It is a kind of innovative precision injection technology. It fills the products by the expansion of air holes and completes the molding of the products under low and average pressure. The microcellular foam injection molding process can be divided into three stages: First, the supercritical fluid (carbon dioxide or nitrogen) is dissolved into the hot melt adhesive to form a single-phase solution; then, the mold cavity with low temperature and pressure is shot through the switch nozzle, and a large number of bubble cores are formed in the product due to the molecular instability caused by the decrease of temperature and pressure, and these bubble cores grow up gradually to form micro particles Small holes.

Process Characteristics:

● Precision injection molding

● Breaking through many limitations of traditional injection molding, it can significantly reduce the weight of parts and shorten the molding cycle

● The warpage deformation and dimensional stability of the parts are greatly improved