Sometimes we find that the reason for the so-called unqualified processing quality of injection mold parts may not be the quality of the mold, but the improper installation and adjustment of the mold. Improper die installation and adjustment is also an important reason to aggravate die wear and cause die safety accidents. This article is going to share the things you should know to improve the quality of plastic injection mold in manufacturing.

Precision inspection during the processing and use of injection mold

Therefore, when starting the processing and production of injection molded parts, trial produce and inspect several initial parts, and compare the inspection results with the accuracy inspection results before the mold is put into storage or the last part inspection results during the last use, so as to confirm whether the installation and adjustment of the mold are correct. And before the mass production of parts, the first parts must be inspected and qualified before they can be started.

In the process of mold processing and production, several parts shall be selected for sampling inspection after a specific injection interval or a specific number of parts are produced, that is, intermediate inspection. The purpose of intermediate inspection is to understand the wear speed of various parts of the mold when in use, and evaluate the impact of the wear speed of the mold on the precision of the mold and the quality of parts, to avoid various unqualified products in batches.

After the production of the mold is completed, the product quality shall be checked again, and the wear degree of each part of the mold and the need for repair or reprocessing of the mold shall be judged in combination with the inspection of the appearance of the mold. In addition, by comparing the results of the initial part inspection and the final part inspection, the wear speed of the die can be measured to facilitate the reasonable arrangement of the production batch of parts for the next operation and avoid the loss caused by the interruption of the operation due to the need for regrinding or repair during the next use of the die.

During the repair of injection mold, the replacement of parts and the disassembly, assembly and adjustment of the mold may greatly change the accuracy of each part. Therefore, the accuracy shall be checked again after the repair. The main inspection methods and requirements are the same as those before the warehousing of new molds.

How to improve the quality of plastic molds from details in manufacturing

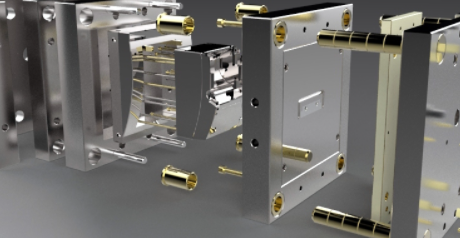

The processing and manufacturing of plastic molds is a particularly complex process. From the initial steps of mold design, processing, assembly and commissioning to the final steps that can be really put into production, the impact of each processing process and process on the quality of plastic molds must be considered in the whole production and processing, and every detail must be done in place, In this way, the quality of the final plastic mold can be guaranteed. So how to control the details and improve the quality?

1. Selection of mold steel: the quality of steel directly affects the quality of plastic mold. It is very important to select materials with good performance and heat resistance, so that the products produced are the best. Mingyang Yutong’s engineers will analyze what materials are suitable according to the characteristics of customers’ plastic products, and suggest customers to choose steel with appropriate product characteristics.

2. Scientific and reasonable plastic mold design: analyze customer products, use scientific mold structure, complete the scientific analysis of the suitability of mold parts, the usability of mold structure and the feasibility of technical processing, formulate and implement corresponding specifications.

3. Perfect processing technology: perfect processing technology process, cooperate with the processing technology manual of each process. Start with the details. Do not let any step go wrong, otherwise, it will cause quality problems in the produced plastic mold, resulting in the plastic mold can not be used or shortening the service life.

4. Mold assembly: Flying mold and assembly of plastic mold is very detailed work. The mold master should ensure that every part and screw can not make mistakes, otherwise, it will cause quite serious consequences. During assembly, pay special attention to the cleaning of the mold, especially the waterways and screw holes. Be sure to blow away the iron filings inside.

5. Plastic mold maintenance: mold maintenance is mainly the maintenance and repair in the production process. After each use of the mold, comprehensive maintenance shall be carried out, especially the rust prevention of the forming part and the rust prevention of the main moving parts. Because the mold production process should be connected with water and cooled down. It is possible to get water on the mold during installation or disassembly, so make sure the mold is dry, and then brush a layer of oil for protection.