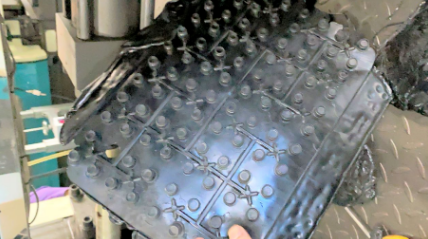

During the process of injection molding, on some materials, a nasty thick buildup can occur over time on the cavity surfaces, causing appearance and sticking issues. These deposits can be very difficult to remove. Here are some tips on how to remove mold buildup after injection molding.

Formation Of Mould Buildup & Deposits

Mold fouling occurs in almost all thermoplastics during injection molding. When the functional requirements of the final product must be mixed with relevant additives (such as modifier, fire retardant, etc.), these additives are likely to remain on the surface of the mold cavity during the molding process, resulting in the formation of in-mold deposits.

There are other reasons for the formation of mold buildup, the most common reasons are as follows:

● Thermal decomposition products of raw materials.

● During injection molding, the extreme shear force of melt flow was observed.

● Improper exhaust.

Type Of Mould Buildup

1. Various additives produce specific types of in-mould deposits. The fire retardant will react at high temperature to form decomposition and may produce scale products. Under the influence of excessive high temperature or extreme shear stress, the impact agent will be separated from the polymer and remain on the surface of mold cavity to form in-mould deposits.

2. The melting of pigments in thermoplastic engineering plastics at high temperature will reduce the thermal stability of molding materials, resulting in the formation of deposit by the combination of degraded polymers and decomposed pigments.

3. Particularly hot parts (such as mold cores), modifiers / stabilizers and other additives may adhere to the surface of the mold and cause mold fouling. In this case, measures must be taken to achieve better mold temperature control or to use special stabilizers.

Countermeasures For Sudden In-Mold Deposit Formation

If mold deposit occurs suddenly, it may be due to the change of molding conditions or the change of different batches of molding materials. The following recommendations will help to improve mold deposit.

● First of all, measure the temperature of the melt and visually check whether there is decomposition phenomenon. At the same time, check whether the molding raw materials are contaminated by foreign substances and whether the same cleaning raw materials are used. Check the exhaust condition of the mould.

● Once again, check the operation of the machine: use dye colored molding materials, after about 20 minutes, close the injection molding machine, remove the nozzle and connecting seat, if possible, dismantle with the screw, check whether there are burnt particles in the raw materials, compare the colors of raw materials, and quickly find out the source of mold buildup.

The screw is suitable for the injection molding machine with the largest diameter of 40mm. The elimination of mould deposit can also improve the quality of the products. The above countermeasures are also applicable to the forming of hot runner system.

In-mould deposit causes appearance defects of injection molded parts, especially parts with surface etch, which can be repaired by sandblasting machine.

Injection Mold Maintenance

When all the above measures can not eliminate the mold buildup, the mold maintenance must be strengthened. Mold buildup on the mold surface is easy to remove at the initial stage, so mold cavity and exhaust channel must be cleaned and maintained regularly. It is very difficult and time-consuming to remove the mold buildup after the mold forms a thick layer without mold maintenance and maintenance for a long time.

Injection mold maintenance and maintenance of the spray used are mainly: mold release agent, rust inhibitor, thimble oil, glue stain remover, mold cleaning agent, etc. The chemical composition of mould buildup is very complex, and new methods must be used and tried to remove it, such as general solvents and various special solvents, oven spray, lemonade containing caffeine, etc.

Suggestions On Prevention Of Mould Buildup

1. When hot runner injection molding and heat sensitive raw materials are used, the residence time of melt will be longer, which increases the risk of deposit formation due to decomposition of raw materials. Clean the screw of injection molding machine.

2. Large size runner and gate are used in forming shear sensitive raw materials. Multi point gate can reduce flow distance, low injection speed and reduce the risk of mold deposit formation.

3. Efficient injection mould exhaust can reduce the possibility of mold buildup formation, and appropriate mold exhaust should be set in the mold design stage. The best choice is to automatically remove the exhaust system or to easily remove the mould buildup. The improvement of the exhaust system often leads to the reduction of deposit on the mold.

4. A special non stick coating on the surface of die cavity can prevent the formation of mold scale. The effect of coating should be evaluated by testing.

5. Titanium nitride treatment on the inner surface of the mold can avoid the formation of mold buildup.