In our daily life, many plastic products only can be made by plastic injection mold process, so plastic injection mold plays a very important role in industrial manufacturing. When users use the injection mold, in order to make it have long-term accuracy and longer service life value, the effective maintenance of plastic injection mold is very necessary. Then how to maintain & care for plastic injection mold?

What Is Mold Maintenance?

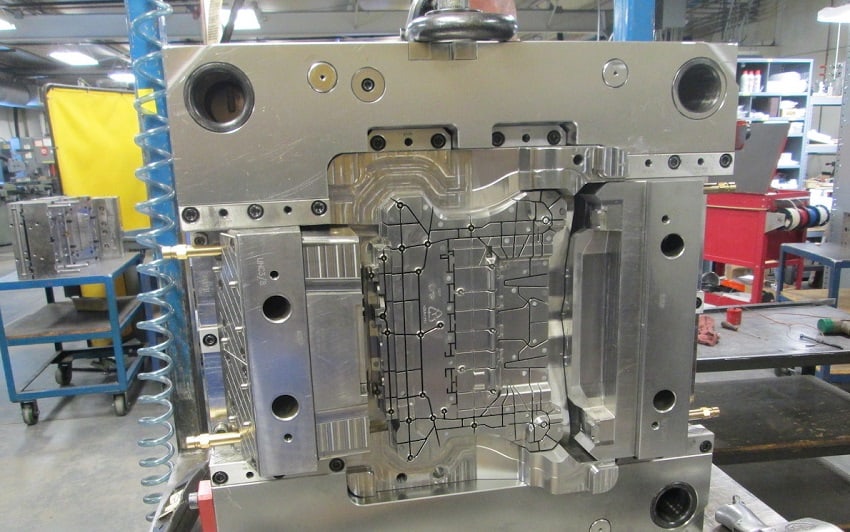

Mold maintenance & tool maintenance refers to the cleaning and repairs that are needed to keep an injection mold in the best working order. Maintenance is performed routinely over the life of the mold, and also when any problems arise. Regular, careful maintenance can prevent part failures and lower the overall cost of your injection molding program.

Plastic Injection Mold Maintenance & Care Instructions – How To Maintain Injection Moulding

2. Under the normal operation of the injection molding, various properties of the mold shall be tested, and the size of the plastic injection molded parts shall be measured. Through these information, the existing status of the mold can be determined, and the damage of the cavity, core, cooling system and parting surface can be found out. According to the information provided by the plastic mold parts, the damage status of the mold and the maintenance measures can be determined.

3. We should pay attention to the surface maintenance of plastic injection mold, which directly affects the surface quality of the product, and the key is to prevent corrosion. Therefore, it is particularly important to select a suitable and professional antirust oil. After the mold completes the production task, different methods should be adopted according to different injection molding to carefully remove the residual injection molding. Copper rod, copper wire and professional mold cleaner can be used to remove the residual injection molding and other deposits in the mold, and then dry.

It is forbidden to clean hard objects such as wire and steel bar to avoid scratching the surface. If there are rust spots caused by corrosive injection molding, it is necessary to use a grinder to grind and polish, spray with professional antirust oil, and then store the mold in a dry, cool and dust-free place.

4. Several important parts of plastic injection mold should be tracked and tested: ejection and guide parts are used to ensure the opening and closing movement of mold and ejection of plastic parts. If any injection molded part is stuck due to damage, it will lead to production halt. Therefore, the lubrication of mold thimble and guide pillar should be kept regularly, and check whether the thimble and guide post are deformed and damaged on the surface, and replace them in time once found.

5. Clean the injection mold regularly is which can ensure the sanitation of the mold. For the production of products, the injection molded products produced by clean and sanitary plastic injection mold are better, and this will not make the mold polluted.