9

2024.12

What Industries Commonly Use Polyimide Injection Molding

Polyimide injection molding is essential for making strong and reliable additives for unique industries. We’ll explain the way it works, the industries that use it, its advantages, and the challenges it faces. You can even examine a leading employer, Plasticinjiectionmould, that gives high-performance plastics manufacturing. What Is Polyimide Injection Molding and How Does It Work?Thermoplastic injection molding is a methodology for making added substances using a......

9

2024.12

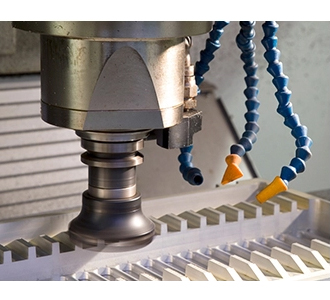

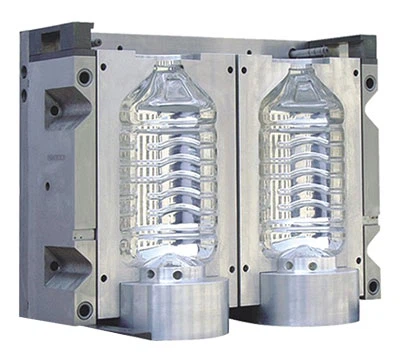

What Is Plastic Injection Molding and How Does It Work

Plastic injection molding is a way to make plastic things. First, the plastic is heated and melts like water. Then, the melted plastic is pushed into a mold. The mold shapes the plastic into anything you want. After it cools, it hardens and keeps its shape. This process is fast and can make a lot of things at once, like toys or bottles. Key Steps in the Plastic Injection MoldingPlastic injection-molding is a simple way to make plastic parts. First, plastic is smal......

1

2024.12

6 Benefits of PEEK Plastic Injection Moulding Service

PEEK (Polyether Ether Ketone) plastic has become the best choice in high-performance thermoplastics manufacturing because of its excellent properties. Known for its power, warmth resistance, and sturdiness, PEEK is extensively carried out in industries like medical, aerospace, vehicle, and packaging. The injection moulding method for PEEK plastic combines precision and efficiency, making it the best for producing extraordinary components. We explore the benefits o......

1

2024.12

What Should I Know About Nylon Plastic Injection Moulding

Nylon plastic injection molding is a vital procedure in international production. It produces long-lasting, lightweight, and flexible factors used in numerous industries. From car components to normal customer merchandise, nylon injection molding plays an important function in meeting present-day production dreams. Learn what nylon is, where Injection molded nylon components are used, and what have to you know about nylon plastic injection moulding. What is Nylon?......

25

2024.11

LDPE Injection Molding: Techniques, Advantages & Common Uses

LDPE, or low-density polyethylene, is a famous plastic material. It’s slight, flexible, and robust, ideal for many products. One of the most unusual techniques for forming LDPE is injection molding. This manufacturing technique is fast, green, and reliable. This article will explain how LDPE injection molding works, its benefits, and its traditional use. We’ll also answer a few frequently asked questions about this technique.What Is LDPE Injection Molding?Injectio......