25

2024.11

PTFE Compression Molding: Process, Benefits & Applications

PTFE, or polytetrafluoroethylene, is an exquisite material with properties that make it treasured for many industries. It is known for its durability, warmth resistance, chemical resistance, and slippery floor. One of the beautiful ways to form PTFE into usable components is through compression molding. This green and dependable method allows manufacturers to create custom shapes and sizes. In this article, we’ll explain the polytetrafluoroethylene molding process......

17

2024.11

Why Soft Plastic Molding Services Ideal for Custom Products

Soft plastic molding is a sport-changer in the production world. It offers flexibility, precision, and performance, particularly for growing custom merchandise and prototypes. This approach is ideal whether you want a one-of-a-kind design or a take-a-look-at version. Let’s explore why gentle plastic molding offerings are perfect and how they gain numerous industries.What is Soft Plastic Molding?Soft plastic molding is a process in which liquid plastic is formed in......

17

2024.11

Top Benefits of Choosing Injection Overmolding Services

Custom plastic overmolding solutions is a game-changer in international production. It combines materials into a single product, giving it better electricity, features, and design. This approach can be the solution you desire to improve your manufacturing method. Let’s explore the top benefits of selecting injection over-molding offerings.Top Benefits of Choosing Injection Overmolding Services for Your Manufacturing NeedsEnhanced Product DurabilityMulti-material i......

11

2024.11

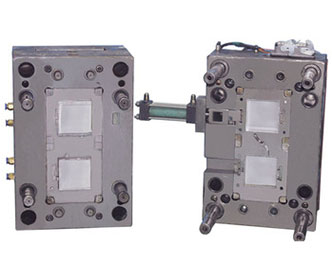

What Is Insert Molding? Process, Considerations & Applications

Insert molding is an injection molding method where steel or other non-plastic components are positioned into a mold, and plastic is injected spherically to form one stable piece. This technique combines one-of-a-kind materials in a single product, growing durable objects without using adhesives or screws. It’s an efficient technique to make merchandise stronger, lighter, and much less likely to go back aside. Let’s explore how metal insert molding works, essentia......

11

2024.11

5 Common Plastic Resins Used in Injection Molding

Injection molding is a popular gadget used to make numerous plastic items, and we consistently utilize it. This strategy comprises liquefying plastic and infusing it into a form to shape objects with extraordinary shapes. Choosing the suitable plastic resin is critical because of the truth each form of plastic is taken into consideration in all types of homes. Some are strong, a few are flexible, and a few can withstand hot temperatures. Here are 5 standard plasti......