6

2024.11

Optimizing Cooling Time for Precision and Efficiency

In injection molding, cooling time is a critical phase that impacts cycle duration, product quality, and overall production costs. With precise cooling techniques, manufacturers can achieve greater efficiency, reduce part defects, and enhance product durability. This blog explores the significance of cooling time, key factors influencing it, and techniques for optimizing the cooling process.The Role of Cooling in Injection MoldingThe cooling stage in injection mol......

4

2024.11

Benefits of Hot Runner Systems in Plastic Injection Molding

Hot runner structures are extensively utilized in Injection mold technology. They have become a popular choice for producers due to their efficiency and the high-quality consequences they produce. But what are the benefits of hot runner system in plastic injection molding? Let’s dive into why those structures are valuable and how they improve the molding process.What is a Hot Runner System?A hot runner machine keeps melted plastic hot through channels inside the m......

4

2024.11

Hot Runner vs. Cold Runner: Which Injection Mould is Best

Selecting between a hot runner system and cold-runner structures is essential when injection molding involves hot-runner molds. These structures have specific hot runner mold benefits, and each fits distinctive production desires. In this article, we’ll explore cold runner vs. hot runner, their pros and cons, and which is probably best for your needs. Let’s dive in!What is an Injection Mould Runner System?An Injection mold technology is a pathway through which me......

28

2024.10

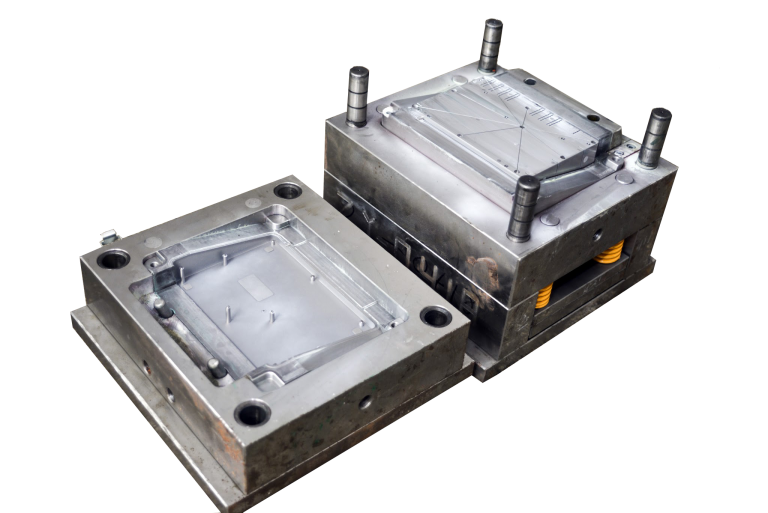

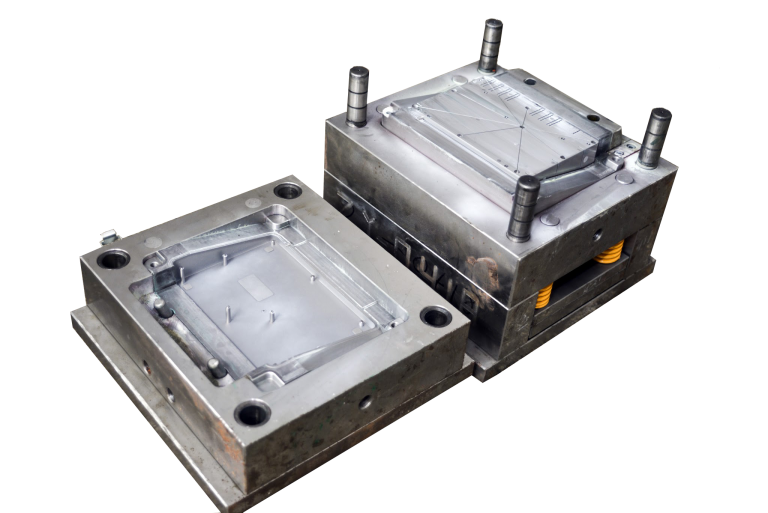

Plastic Injection Mold vs. Other Molding Techniques: Which is Best

Manufacturers have numerous molding techniques to pick from when making plastic components or merchandise, with every method imparting its very non-public advantages. Among those, plastic injection molding is the most well-known preference. But is it first-rate? Let’s dive into the Injection molding process and how it compares to big molding techniques and help you decide which approach is probably tremendous for your venture.What Is Plastic Injection Molding?Plas......

28

2024.10

Top Benefits of Using Plastic Injection Mold in Manufacturing

Plastic injection molding is a famous technique used in manufacturing today. This approach makes it clean to create vast quantities of plastic parts high in the best element. With the assistance of a mold, melted plastic is injected into the desired shape, making production speedy, unique, and efficient. The injection molding process offers many blessings, especially in industries like electronics, toys, automobiles, and medical gadgets. The top benefits of using ......