27

2023.3

About Compression Molding 2023

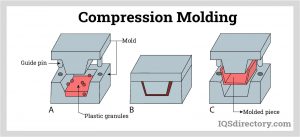

Compression molding is a process in which plastic materials are placed in a heated mold and then pressed into a specific shape. This process involves cooling, trimming, and then removing the plastic part from the mold. Compression molding offers many advantages, such as cost-effectiveness and efficiency. These benefits make compression molding an attractive process for manufacturing unique parts. In addition to these advantages, compression molding allows for the ......

23

2023.3

Injection Moulding: An Ideal Solution for Packaging Solutions – Part 2

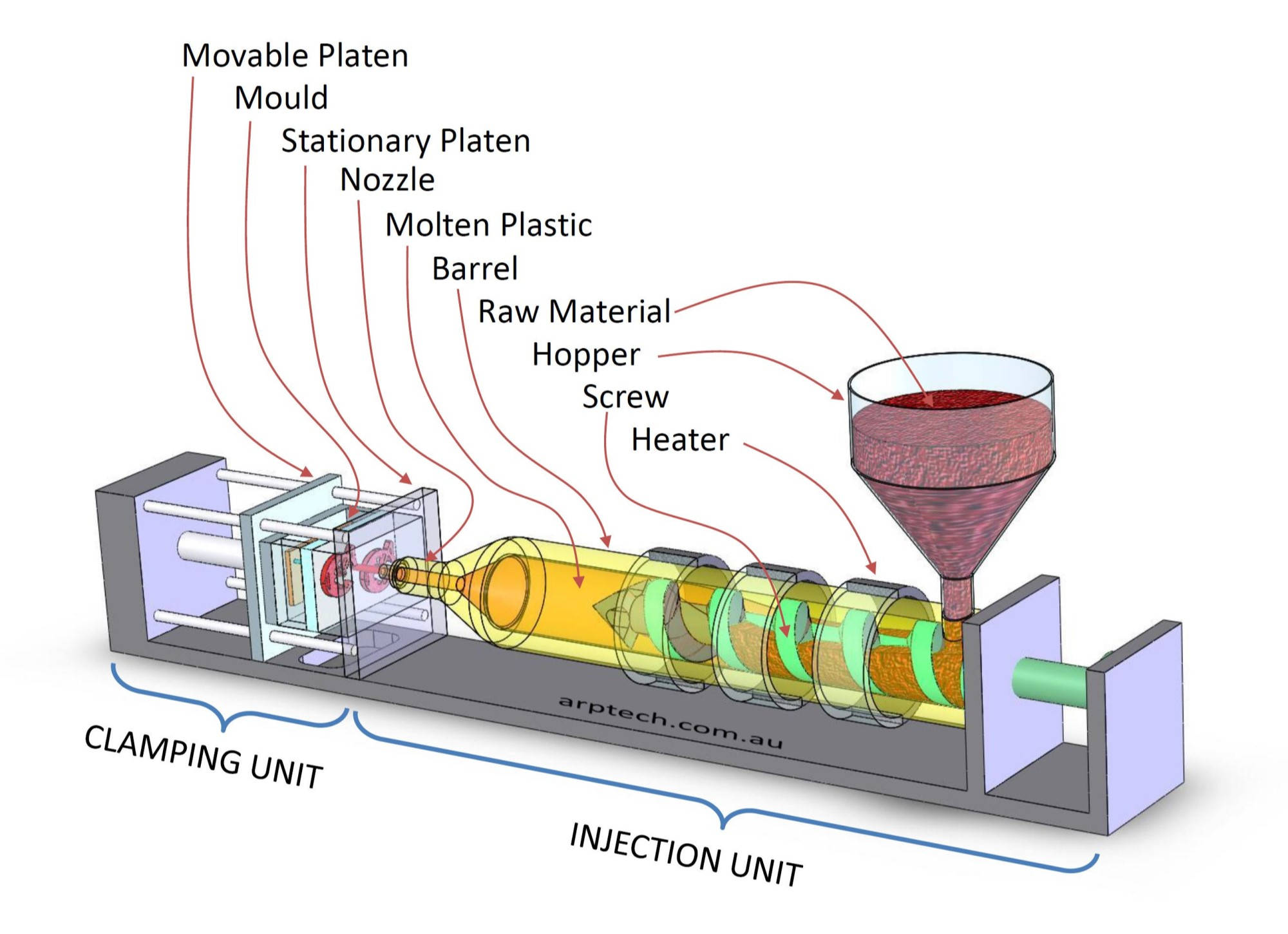

4 Types of Molding Processes: Applications and Advantages:Molding is one of the five core processes in rubber and plastic manufacturing, alongside casting, forming, machining, and additive manufacturing (AM). Molding involves a process of compressing and molding a thermoplastic material (e.g., plastic) to create a product (e.g., a bottle) or component (e.g., a ring) of that material. The process of molding involves the injection of the polymer into a mold (e.g., m......

21

2023.3

Injection Moulding: An Ideal Solution for Packaging Solutions – Part 1

Injection Moulding: An Ideal Solution for Packaging Solutions There is no shortage of packaging options available today. Each manufacturer has its own packaging requirements, and packaging has become more and more challenging for businesses each day. Whether it’s food packaging, pharmaceutical packaging, or other packaging solutions, the process of injection molding is important for businesses to ensure the quality of their products. At Matrix Injection Molding (M......

18

2023.3

Reduce Expenses and Increase Efficiency with Packaging Molds

Reduce Expenses and Increase Efficiency with Packaging Molds Packaging is the first impression that customers get of your brand, and it can make or break the customer’s experience. Good packaging helps to ensure the products are protected and reach the customer in top condition. More often than not, packaging mistakes can be costly. The cost of packaging errors can be significant for retailers and manufacturers. In order to avoid packaging mistakes, retailers shou......

16

2023.3

Take Your Product Design to the Next Level with Plastic Injection Molding – Part 2

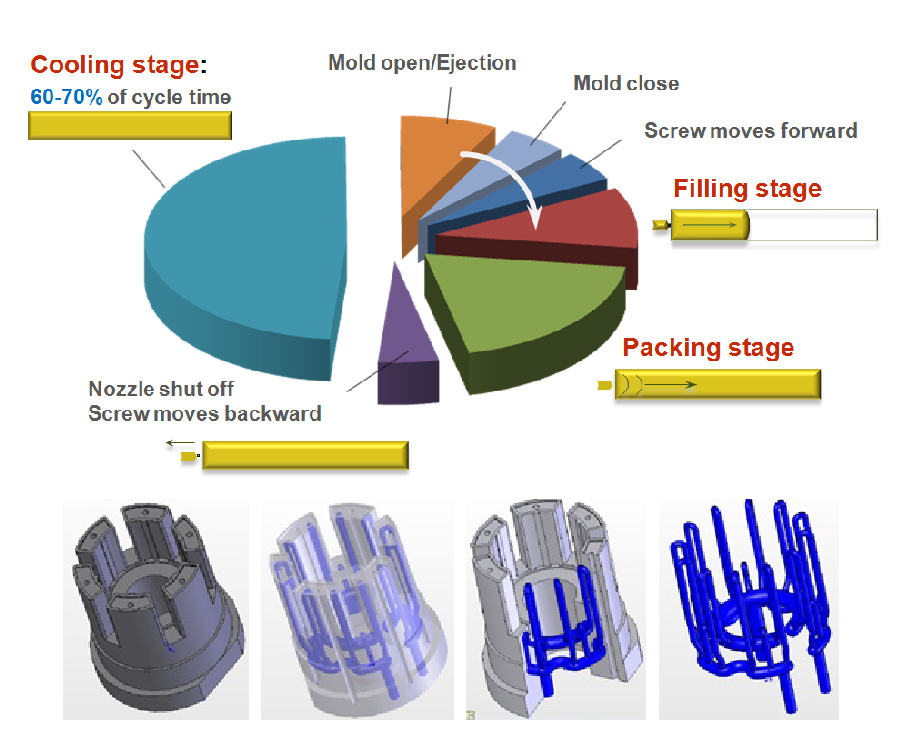

Why Use Injection Molding? With injection molding, parts or products can be created quickly and efficiently. This process also offers high precision and accuracy, making it a great choice for cost-conscious manufacturing. The ability to create parts quickly also makes it an attractive process for 3D printing. Additionally, injection molding can be environmentally friendly and secure due to its closed loop process. Click Here to Read Part 1stInjection process:Inje......