13

2023.3

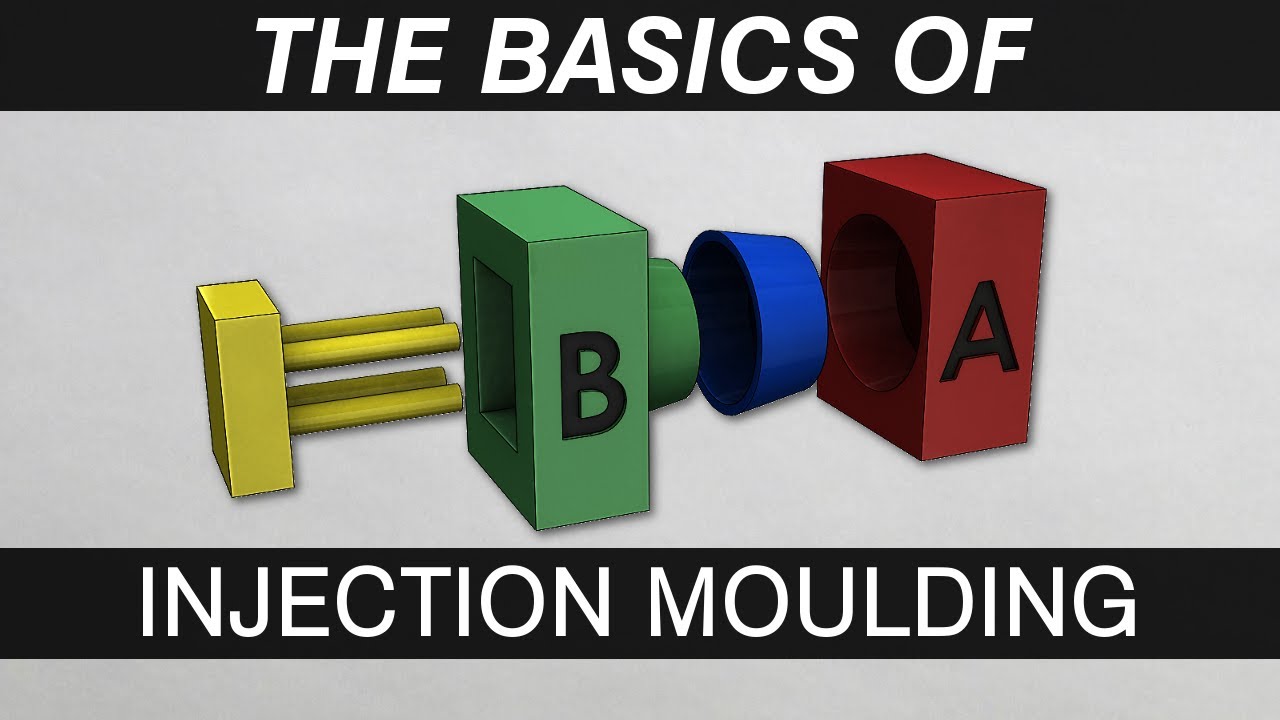

Take Your Product Design to the Next Level with Plastic Injection Molding – Part 1

The plastic injection molding process is one of the most versatile methods used in product manufacturing. It involves injection molding resin into a part patterned on a material injection machine. The process provides products with mass production capability and consistency required for high-volume manufacturing.The injection molding process is ideal for making plastic parts of various shapes and sizes, from small parts to large containers. It is also used to make......

10

2023.3

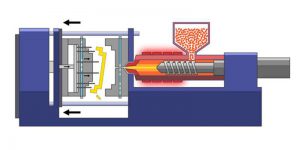

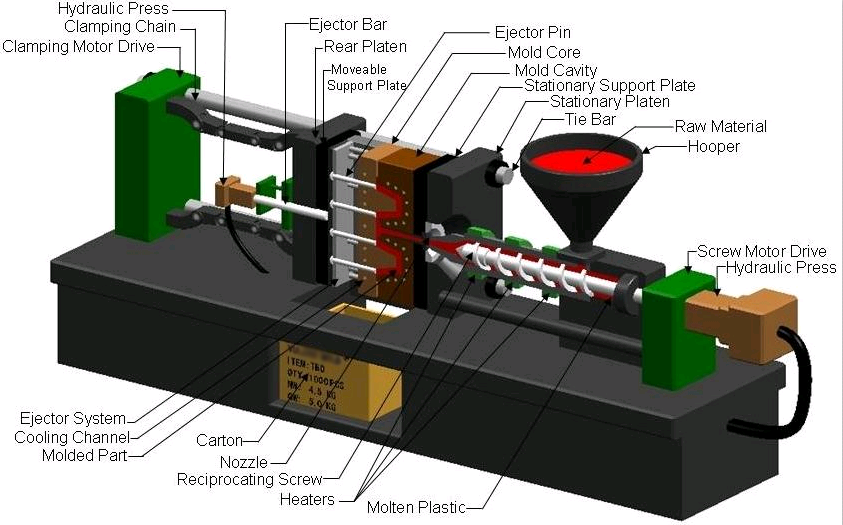

Uncover the Magic Behind Plastic Injection Molding Part -2

How Does Plastic Injection Molding Work?With plastic injection molding, plastic parts are made by injecting molten plastic material into a mold at high pressure. In the process, the polymer is heated to high temperatures and then injected into the molding machine. The plastic is forced to solidify in the form of a part and is then cooled to remove it from the machine. This process is used in manufacturing various types of parts, including injection molding machin......

8

2023.3

Uncover the Magic Behind Plastic Injection Molding – Part 1

Behind Plastic injection molding is a manufacturing process that creates injection molds for plastic parts and packaging. The process involves heating thermoplastic material to high temperature, injection molding it into the mold cavity, cooling the part, and ejecting it from the mold. The process is useful for the mass production of plastic parts because it speeds up the design process, material selection, mold production, injection molding tooling costs, part ma......

6

2023.3

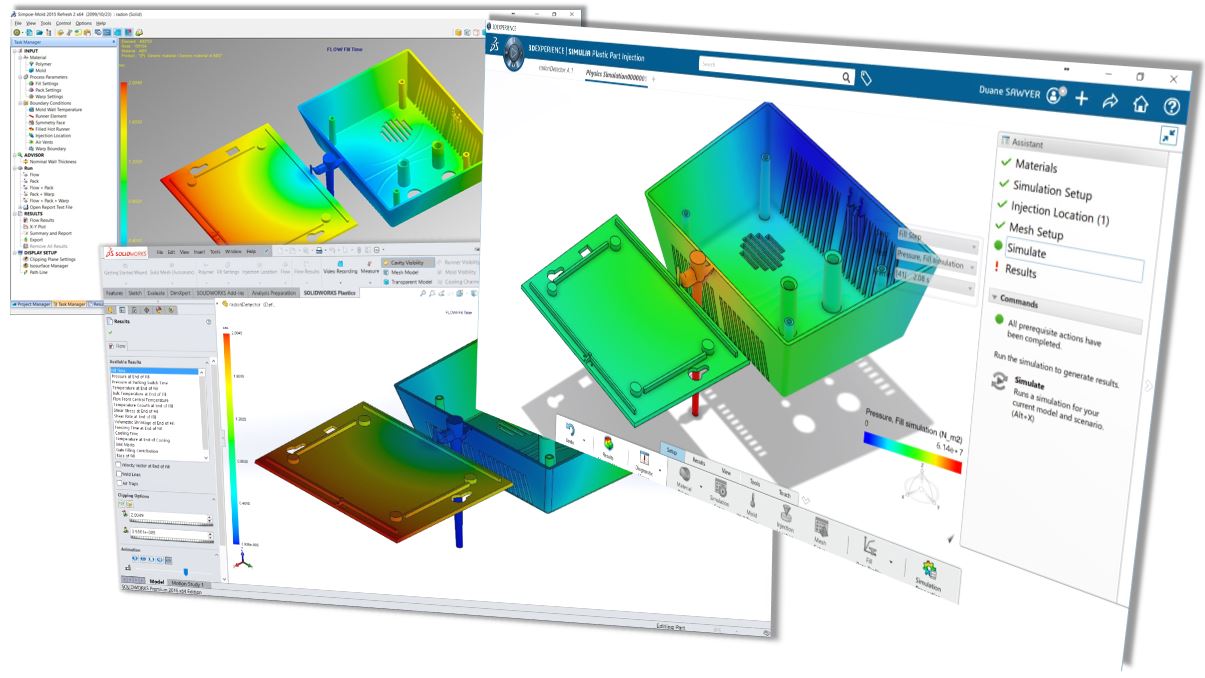

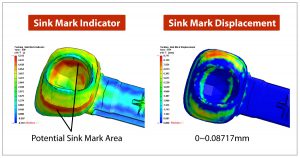

Solving the problem of injection molding sink marks

For injection molding specifications, sink marks can ruin a part’s aesthetic look and finish. Sink marks are a common issue in the injection molding process, but it doesn’t have to be this way. With the proper set of considerations, you can reduce or eliminate sink marks from your parts using intelligent choices for design details like gate location, wall thicknesses, and draft angles. To help ensure successful performance goals with minimal product variations due......

3

2023.3

5-way solution injection molding sync sign

Are you looking for a way to maximize efficiency, reduce costs, and increase productivity with your injection molding sync sign? We hear you. Injection Molding is an incredibly complex process requiring tight communication between the shop-floor and planners or other personnel running the production sequences in order to remain cost effective. All too often these processes break down due to several challenges that need solutions—that’s where we can help! Drawing o......