27

2020.11

Liquid Silicone Rubber Injection Molding Process From Start To Finish

The injection molding of liquid silicone rubber is a new technology rising in rubber processing in recent years. The characteristic of this process is that it can produce silicone rubber products at high speed. Here in this article, we overview the introduction to liquid silicone rubber injection molding and process of LSR injection molding from start to finish. What Is Liquid Silicone Rubber & SLR Injection Molding?Liquid silicone rubber has existed since t......

25

2020.11

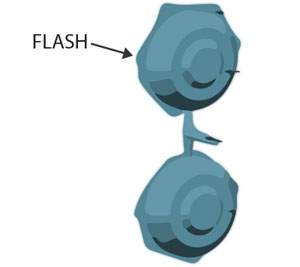

What Causes Flash In Injection Molding & How To Fix Them | Moldplasticinjection

Flash is one of the most common defects in the injection molding industry. In the production of injection molded parts, the first process after demolding is to manually scrape off the flash, which will undoubtedly reduce the productivity and directly affect the appearance quality of the plastic part. In the plastic injection molding process, because the mold is subjected to the complex influence of various external factors, it often causes the distortion of the mo......

25

2020.11

Preventive Maintenance Of Injection Molding Machine – Hydraulic, Electrical And Mechanical

Injection molding machine is one of the widely used equipment in the plastic processing industry, usually it has to work for a long time. Therefore, how to ensure the normal and stable operation of the injection molding machine in continuous production is a problem worthy of attention and efforts to solve. From the perspective of users, regular preventive maintenance is an effective way to ensure the normal operation of the injection machine under the premise of c......

14

2020.11

Polypropylene (PP) Injection Molding Process – 11 Common Defects In PP Injection Molding

The injection molding process of plastic raw materials is mainly plasticizing, filling, cooling and shaping to become finished products. It is a process of heating and then cooling, and also the process of plastic changing from particles to different shapes. In this article, we will explain the PP injection molding process from the perspective of different stages and we present 11 common defects in Polypropylene injection molding. Injection Molding Process For Pol......

30

2020.10

Injection molding is very important to our industries, its main advantages are production speed, high efficiency and can realize automation operation. If you have a project that needs plastic injection molding service, then you should first understand the basic parameters of injection molding process. Below article introduces 8 important parameter for injection molding production. Basic Parameters Of Injection Molding Process1.TemperatureTemperature measurement a......