27

2020.10

Sink Marks In Plastic Injection Mold – What Causes Sink Marks And How To Fix Them?

There’s a variety of defects that could potentially affect a molded part include short shot, burning, weld line, warpage, peeliing, parting line, sink mark and more. Today’s focus is going to be on one of the most common injection molding defects – Sink Marks which primarily is more of a surface quality issue but depending on the application. We detail the sink marks in plastic injection mold, what causes sink marks and how to avoid sink marks in your plasti......

23

2020.10

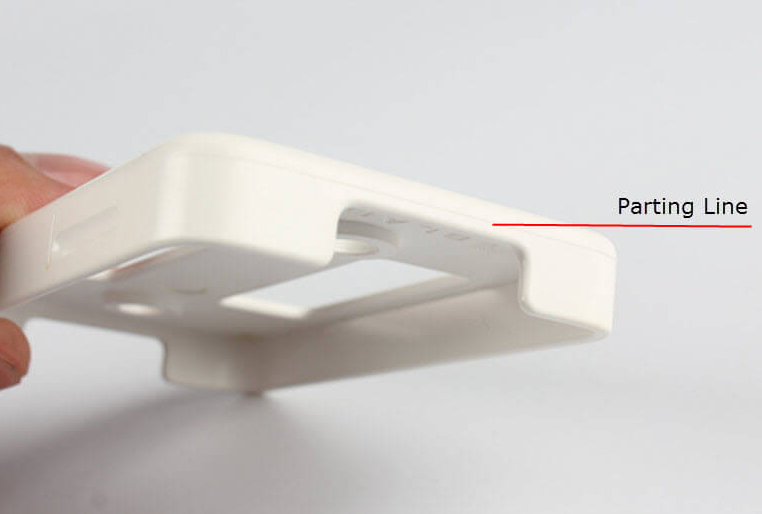

Parting Lines In Injection Molding – Tips To Choose Parting Line Right For Mold Design

Parting line selection is very crucial & important part of mould design process. You should know about parting line position of plastic components. Accordingly, this guide covers the definition of injection molding parting line, types of parting lines for plastic injection molded parts, and tips to choose parting line right. What Is Parting Line In Injection Molding?With injection moulding parts it’s impossible to avoid a parting line – which is is mark......

20

2020.10

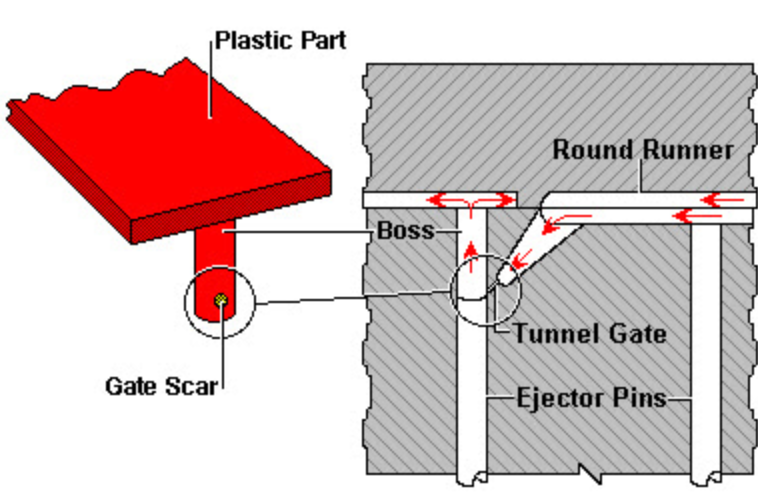

Injection Molding Gate Location – 5 Tips To Choose The Right Gate Location For Mold

In plastic injection molding, the “gate” is the opening in a mold through which the molten plastic is forced into the cavity, the tooling representation of your part. The type of gate and its location are critical, they can make or break a part. The placement of the gate can also affect many aspects of a project. So how can we choose the right gate location for mold? Check out this article and get to know the gate on injection mold and gate location selecting skil......

9

2020.10

What Is The Best Way To Control The Dimensions Of Injection Mold Products? How To Control?

The shape accuracy of injection molded parts should meet the strict dimensional tolerance, geometric tolerance and surface roughness. In order to carry out precision injection molding, there must be many related conditions, and the most essential factors are injection mold design, injection molding process and general production. Read on the article and get to know more details. How To Control The Dimensions Of Injection Mold Products?Mold Design Control● First o......

29

2020.9

Top 7 Plastic Surface Treatments: Electroplate, Laser Engraving, Conductive Paint & More

Nowadays, plastic products can be seen everywhere in our life, they can be produced by injection moulding process. But now people’s requirements for plastic products are not the same as before, as long as they are easy to use. The appearance should not only be beautiful, but also economical. That is to say, the focus of attention is gradually focused on the sex price ratio. Therefore, the surface treatment of plastic products plays an important role in the m......