27

2020.9

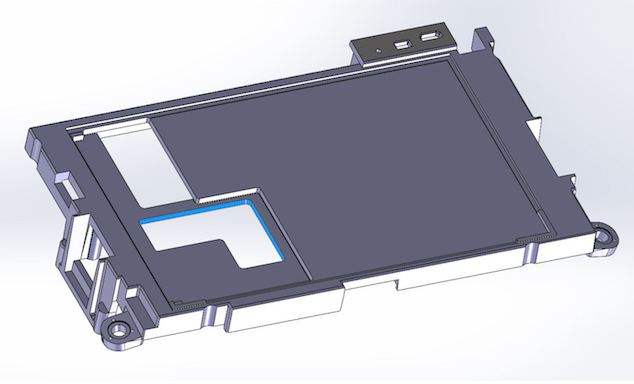

Top 8 Considerations For Designing High Quality Injection Molded Parts Successfully

The injection product design evolves through multiple development stages before all parts are finally recorded and released to the molder for production. The last step in the development process is the most critical because no further design changes or corrections can be made without significant cost increases or project delays. Now here are top 8 considerations shared for you to design injection molded parts successfully. These 8 considerations are by no means ex......

25

2020.9

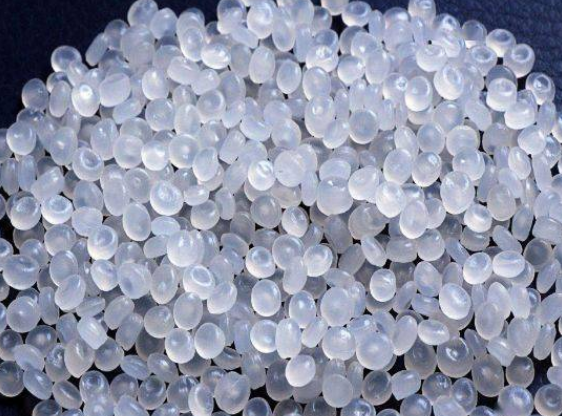

Polypropylene Plastics: Characteristics, Usages, Everything You Should Know About PP Plastic

Polypropylene (PP) is a rigid and crystalline thermoplastic used widely in everyday objects. Read this article and learn everything you need to know about Polypropylene plastics include the characteristics, usages, properties, process, causes & solutions to bubbles in Polypropylene injection molding products. Everything You Should Know About Polypropylene PP PlasticCharacteristics of Polypropylene Plastics, What It’s Used For?Polypropylene has no toxic, taste......

19

2020.9

To produce a plastic product, you need an injection moulding machine. Which is also know as an injection press, the main molding equipment to make thermoplastic or thermosetting materials into various shapes of plastic products by plastic molding mold. There are many different types of molding machines, depending on what you are creating and how the machine affects the product. Divided into vertical injection molding machine, horizontal injection molding machine a......

10

2020.9

Plastic Injection Molding Process Cycle – How To Reduce Cycle Time For Injection Molded Parts

Injection molding is a comprehensive process, it is related to the time of each procedure, so it directly affects the thermal process and stress time of polymer solid melt and products, and affects the product quality and production efficiency. The process cycle for injection molding is very short, typically between 2 seconds and 2 minutes, and consist of four stages including clamping, injection, cooling and ejection. The stages in cycle process for injection mol......

31

2020.8

Nowadays, plastic has become an inevitable trend to replace expensive metal materials in automobile industry. High strength engineering plastics not only reduce the cost of parts processing, assembly and maintenance, but also make the automobile lighter, energy-saving and environmental protection. According to the data, plastics and their composites are the most important lightweight materials for automobiles. It can not only reduce the quality of parts by about 4......