17

2020.3

Injection Moulding Process – 4 Best Polishing Methods For Plastic Injection Molds Making

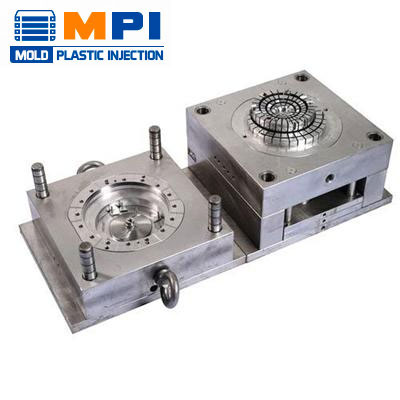

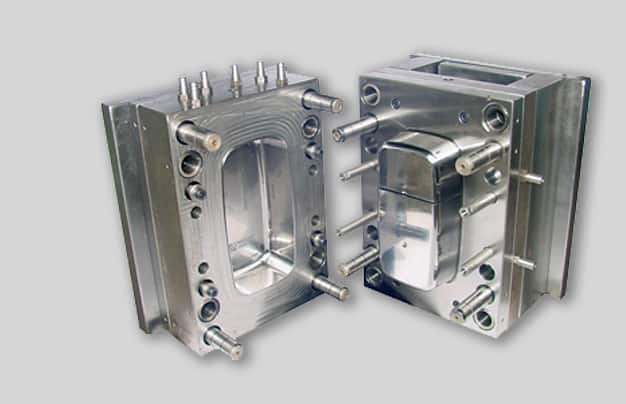

With the widespread application of plastic products, the requirements for the appearance quality of plastic products are becoming higher and higher, and the surface polishing quality of injection mold processing must be improved accordingly, especially the mold surface roughness of mirrors and high-gloss surfaces. The requirements are higher, so the requirements for polishing are also higher. Polishing not only increases the appearance of the workpiece, but also i......

12

2020.3

9 Common FAQs About Heat Treatment Of Injection Mould

Heat treatment is the premise and foundation of a good mold. If your mold heat treatment is not good, you can produce a perfect mold product. Here we will present some common FAQs about heat treatment of injection mold for you to understand mold heat treatment more deeply. Question Answered For Heat Treatment Of Injection Mould What Method Is Used To Check The Effect Of Heat Treatment? Simply check the surface hardness. Accurate inspectio......

12

2020.3

8 Injection Molding Defects & Troubleshooting Tips – How To Fix Common Injection Molding Issues

Injection mold is a tool for producing plastic products, and also a tool for giving plastic products complete structure and accurate size. The structure and processing quality of injection mold directly affect the quality of injection molding products and production efficiency. The following is a brief analysis of some common injection molding defects and their countermeasures.Common Defects And Troubleshooting Tips For Plastic Injection Molding 1.Difficulty In Ga......

6

2020.3

EX MOULD is a China top injection molding company, manufacturer, supplier and exporter, specializes in designing and producing all types of high-quality plastic injection molded products, insert mould, over mould, mould tools including the high-end appearance parts automobile, medical, smart home, instrument, hand tools and more. We offer machining and finishing services to make tools from a variety of materials, and can produce 50 to 100,000+ finished parts......

18

2019.11

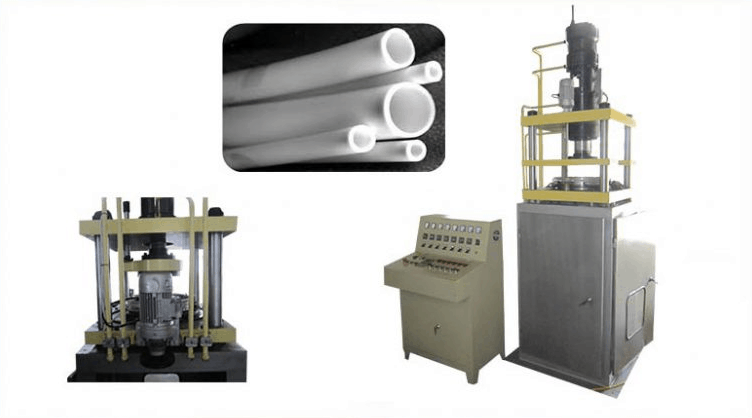

Plastic Overmolding: All you need to know

The intricacies involved in designing and developing a plastic part are often hard to imagine. The technique of plastic injection molding has made it possible to use plastic resins in various industries and applications.However, with some plastic parts, the geometric complexities and the need for additional features like aesthetics, soft-grip surface, etc make it necessary to consider new technologies like plastic overmolding. ......