Do you ever ask why companies that make plastic bottles don’t just buy molds? People ask this a lot. Molds shape bottles. But, many things affect the choices of these companies. Let’s look at why they make these choices and learn about how plastic bottles are made.

Why Molds Matter in Making Plastic Bottles?

Ever wonder how plastic bottles get their shape? It’s all because of molds. Let’s see why molds are so important when we make plastic bottles!

- Giving Shape: Molds are like plans for plastic bottles. They can be many shapes and sizes. The mold decides what the bottle will look like.

- Making Each Bottle the Same: Molds make sure each bottle is the same as the next one. This is important for keeping the quality high and making customers happy.

- Making Different Designs: With molds, we can make bottles in many designs and sizes. This lets us make different bottles for different products and tastes.

- Making Things Faster: Using molds makes the process faster. This lets us make plastic bottles more quickly and efficiently.

- Saving Money: Good molds might cost a lot at first. But in the end, they save money. They cut down on waste and make the process more productive.

- Lasting a Long Time: If we take care of molds, they can last through many heating and cooling cycles. This means they stay strong and last a long time.

- Keeping Up with Changes: As technology gets better, molds change too. They can have new features and designs. This helps us keep up with what customers want and what’s popular.

- Helping the Environment: Using molds well means we waste less material. This helps us make plastic bottles in a way that’s better for the environment.

- Making Sure Bottles Are Good Quality: Molds help us make sure each bottle is good quality. They make sure each bottle is strong, durable, and looks good.

- Always Getting Better: We always try to make molds better. This helps us work more efficiently, make fewer mistakes, and get better results.

Why Don’t Plastic Bottle Makers Buy Molds?

You might wonder why plastic bottle makers don’t buy molds. It seems strange, but there are good reasons for it. Let’s look at these reasons.

Costs

Buying molds costs a lot of money. This can be hard for small or new businesses. After buying, you need to keep the molds in good shape. This means more costs for upkeep and repairs. Also, molds take up space. You need to find room for them in your factory, which can be expensive and tricky.

Flexibility

If you own molds, you can’t change them easily. This can be a problem when you want to make different kinds of bottles. Also, the demand for plastic bottles can change. It can go up or down because of the season, the economy, or trends. So, you need to be able to change your production quickly.

Outsourcing Benefits

When you outsource mold making, you get help from experts. They know a lot about making molds and they use the latest technology. This means you get high-quality molds that meet your needs. Also, you don’t have to worry about upkeep, repairs, or storage. The mold maker takes care of all that. This makes your operations smoother and simpler. Plus, you can change your production more easily. You can order new molds whenever you need them.

Environmental Factors

Today, people care a lot about the environment. So, plastic bottle makers need to think about sustainability. When you outsource molds, you can save materials and energy. Also, you need to follow environmental rules and standards. When you work with a good mold maker, they can help you do this.

Plastic bottle makers choose not to buy molds for practical reasons. They think about costs, flexibility, and the environment. By outsourcing, they can get expert help, work more efficiently, and support sustainability. This helps them deal with the challenges of today’s manufacturing world.

Explanation of the plastic bottle manufacturing process

Ever wonder how we make plastic bottles? Let’s find out!

- Starting with Small Pieces: We start with small pieces called PET pellets. These are the building blocks of plastic bottles.

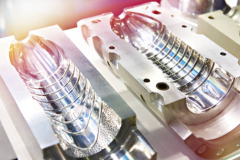

- Melting and Shaping: Next, we heat the PET pellets until they melt. The melted plastic goes into bottle-shaped molds.

- Cooling Down: The hot plastic fills the mold and takes the shape of a bottle. Then, we cool down the mold. This makes the plastic hard and keeps the bottle in shape.

- Trimming Extra Plastic: After the plastic cools and hardens, we cut off any extra plastic around the edges. This makes each bottle look smooth and finished.

- Checking Quality: Before we do anything else, we check each bottle. We make sure it’s strong, durable, and looks good.

- Adding Labels and Packing: After the bottles pass the quality check, we add labels. The labels have the brand name and product information. Then, we pack the bottles and send them to stores.

- Using Machines: Machines and automated systems help us make the bottles. They make the process faster and keep the quality consistent.

- Thinking about the Environment: Plastic bottles are handy, but they can harm the environment. That’s why we need to recycle. Recycling helps reduce waste and protect our planet.

Final Words

To wrap up, molds are very important in making plastic bottles. But, companies don’t always buy them. They think about many things like cost, flexibility, and new technology. They use these to make their processes better. By understanding this, we can learn more about how plastic bottles are made.