22

2022.9

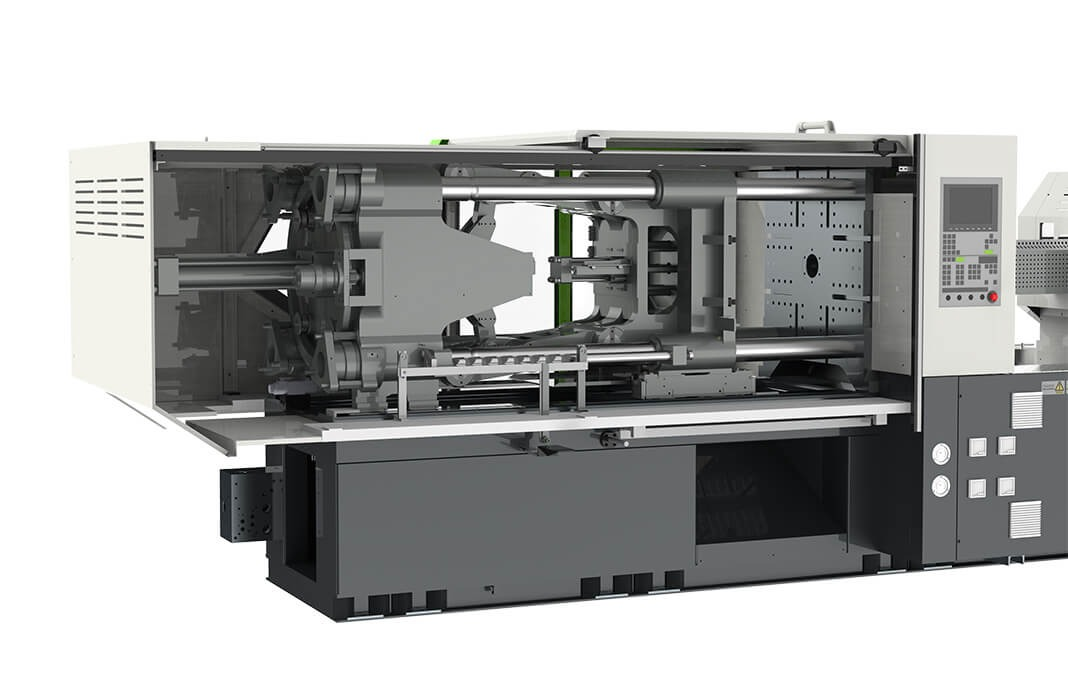

Injection Moulding Machine Process | An Easy 3 Steps Guide

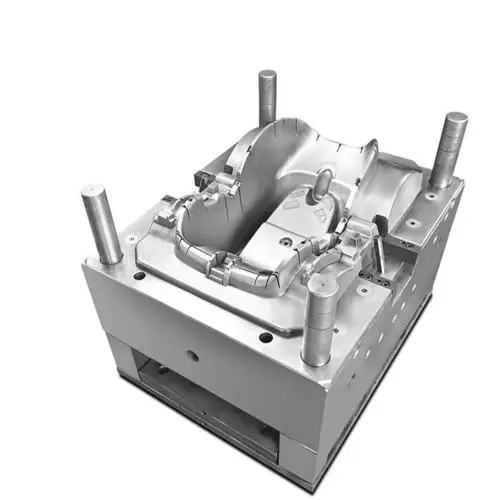

Injection moulding is a process for creating parts and products from various plastic materials. It works by injecting molten plastic into a mould, where it cools and hardens to the shape of the mould. The injection moulding machine process is a versatile manufacturing method that can be used to create a wide variety of parts and products, from simple to complex. Why is the injection moulding machine process used? Injection moulding is a popular manufacturing choice for many reasons. It is relatively quick and easy and can be used to crea......

21

2022.9

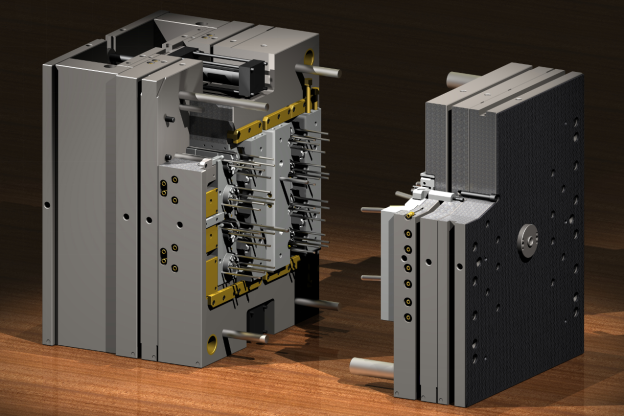

What is a plastic injection mould maker? Injection moulding is a process of producing components that involves injecting the material into a mould. Injection moulds can be manufactured from a variety of materials, including glass, elastomers, confectioners, and, most commonly, thermoplastics or thermosetting polymers. The material from the piece is placed in a heated barrel, mixed using a helical screw, an......

20

2022.3

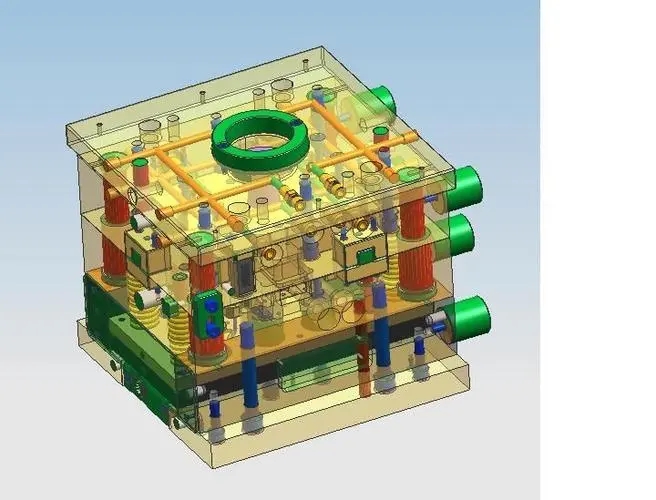

Technology has continuously improved the standardization of plastic molds

With the improvement of the design and processing level of plastic mold enterprises, the manufacturing of molds is changing from mainly relying on the skills of fitters to mainly relying on technology. This is not only the change of production means, but also the change of production mode and the rise of ideas. This trend leads to the continuou......

20

2022.3

New development direction of plastic mould in China Manufacture

As one of the pillar industries of China’s light industry, the growth rate of plastic industry has been maintained at more than 10% in recent years. In the plastic industry, the market of plastic hardware industry is very active and has become a new consumption hotspot and a new economic growth point. The market prospect of plastic mould ......

20

2022.3

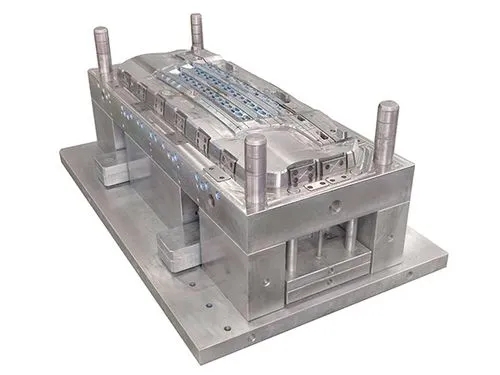

The development of plastic mould and the meaning of plastic mould

All kinds of tools and products used in our daily production and life, ranging from the base and body shell of the machine tool to the shell of a embryo head screw, button and various household appliances, are closely related to the mold. The shape of the mold determines the shape of these products, and the processing quality and accuracy of the mold also determine the quality of these products. Because of the different materials, appearance, specification......