24

2021.2

When it comes to injection molding for parts, the overall size, heart volume, and designer parts will determine if one layout is better than another layout. Since options for injection molding tools come in multiple layouts, we’re going to discuss the three most important in this article. Those are single cavity, family, and multi-cavity tools. Let’s dive in deep, so we can better understand which option is best for your business. #1 Single Cavity......

1

2021.2

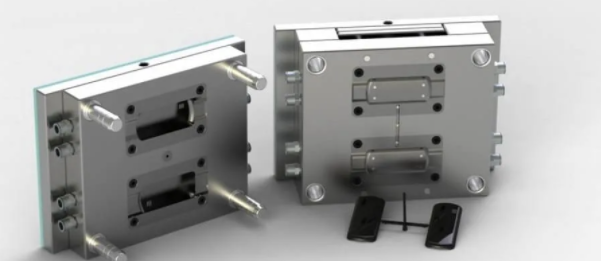

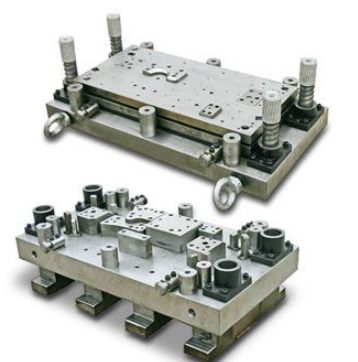

Plastic Molds Manufacturing Process, Design, Definition And Composition

In recent years, with the rapid development of the plastic industry and the continuous improvement of the strength and precision of general and engineering plastics, the application scope of plastic products is also expanding. A reasonably designed plastic part can often replace many traditional metal parts. Why plastic mold products are popular now, the reason you are about to find out. This article is going to show you everything about the manufacturing process......

19

2021.1

What Is The Difference Between Vacuum Forming, Injection Molding And Blow Molding

Mold is a very common tool in the modern industry. Depending on their own shape, certain advanced molding machines to make certain plasticity or fluidity of the material also become a specific shape. There are several types of molding processes like blow molding, compression molding, extrusion molding and more. Today, we are going to show you the difference molding process between injection molding, vacuum forming and blow molding. 1.Vacuum FormingA ki......

15

2021.1

A lot of people might confused what is injection mold cooling system? The design of injection mold cooling system is often considered a secondary problem. Today, this article will show you everything you need to know about injection mold cooling system, as well as its temperature, principle, process and conformal chanels. What is Injection Molding Cooling System? Injection molding cooling temperature is very important for mold design. The correct design of th......

25

2020.12

For an injection molding factory, the injection molding process takes up a large amount of energy, accounting for over 60% of the factory’s overall energy consumption. Thus, the more energy-efficient the injection molding process becomes, the more energy the factory can save. With the continuous development of the injection molding machine’s energy-saving technology itself, reducing the overall energy consumption of injection molding factory needs to b......