28

2021.5

Plastic Hot Runner System In House Cleaning Guide – The Best Hot Runner System Maintenance Method

The Benefits Of Utilize The System Of Hot Runner/Hot Manifold To mold parts more accurately and efficiently, many companies today design their molds with a hot runner or hot manifold system. they have several advantages over cold runner systems including scrap production, minimal gate vestige, improved cycle time, better process control, more park design options, no need for runner removal, robotics, or separators. The Importance Of The Daily Mainten......

28

2021.5

The Perfect Injection Molding Materials – The Injection Molding Of Silicone Rubber

There are not a whole lot of molded components who could withstand abuse like silicon. silicon can be stretched all day long. when you need a part that is flexible, chemically resistant, and inert. our silicone molds & injection molding of silicone rubber services are what you want. The Incredible Features Of Silicone MoldsSilicone molding can be incredibly flexible, not only because of the material itself but also because of the design flexibility.......

28

2021.5

What Is ABS – Applications, Advantages & Injection Molding Of ABS

ABS (acrylonitrile butadiene styrene) is a general thermoplastic engineering plastic developed in the 1940s. It not only has good rigidity, hardness, and processing fluidity but also has high toughness, which can be used for injection molding, extrusion, or thermoforming. Generally speaking, automobile, appliance and an electronic appliance are three application fields of ABS resin. What do you know about ABS and ABS injection molding? Today, at moldplasticinject......

25

2021.5

What Is The Difference Between Thermoset & Thermoplastic?

Do you know what is the difference between thermoset and thermoplastic? Thermoplastics and thermosetting plastics are types of plastics that undergo different production processes and produce various properties according to their constituent materials and production methods. The terms thermoplastic and thermoset represent how materials are processed at varying temperatures. Difference Of Reactions To High Temperatures: 1.Thermoplastics can be like water, it......

13

2021.5

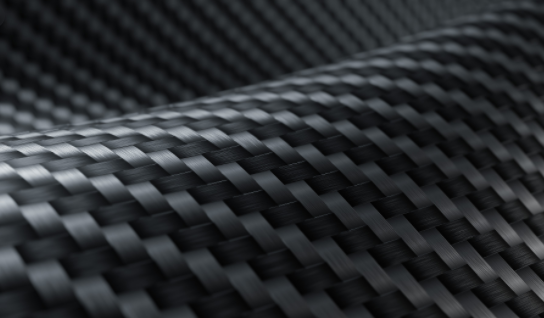

What Are Carbon Fiber Molding Processes?

From prepreg to final parts, carbon fiber composites need to be processed by the molding process. With the development of carbon fiber technology, the molding process of carbon fiber composites is also in constant progress. However, various molding processes of carbon fiber composites do not exist in the way of renewal and elimination. Many processes coexist to achieve the best effect under different conditions and situations. The following is a list of the 12 mo......