19

2021.6

The Best Ways Of Using Plastic Injection Mold Tools To Get The Perfect Surface Textures

Surface textures on molding tools are significant for reasons other than aesthetics. Here are a few examples of topics to think about: Different textures will influence how moldable a part is. Some increase heat transfer between the tool wall and the resin, necessitating the use of alternative cooling solutions. Other texturing will cause the part to cling inside the mold until the draft angle is increased. Because heavily textured surfaces require more dwell......

8

2021.6

Barrel For Injection Molding Machine: Characteristics, Materials, And Strength Calculation

The barrel and screw constitute the extrusion system. Like screw, barrel works under high pressure, high temperature, severe wear and corrosion. In the extrusion process, the barrel can transfer the heat to or from the material. The heating and cooling system shall be set on the barrel and the machine head shall be installed.In addition, the feeding port should be opened on the barrel. The geometry and location of the feeding port have great influence on the feedi......

29

2021.5

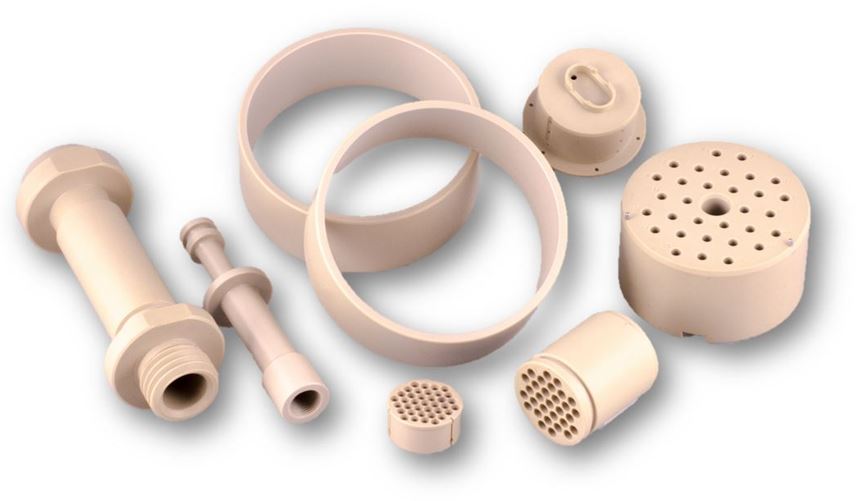

Plastic Injection Molding Material Selecting Guide – Why Choose PEEK Molded Parts

The Incredible Features Of PEEK As A Plastic Injection Molding Material PEEK is considered a high-performance, highly-engineered thermoplastic material. PEEK is an abbreviation for the chemical name Poly-ether-ether-ketone. and PEEK is a member of the PAEK family (Poly-aryl-ether-ketone). PEEK materials are designed to operate at high temperatures up to 480 degrees Fahrenheit or 250 degrees Celsius continuously. this includes the ability to handle exposure......

29

2021.5

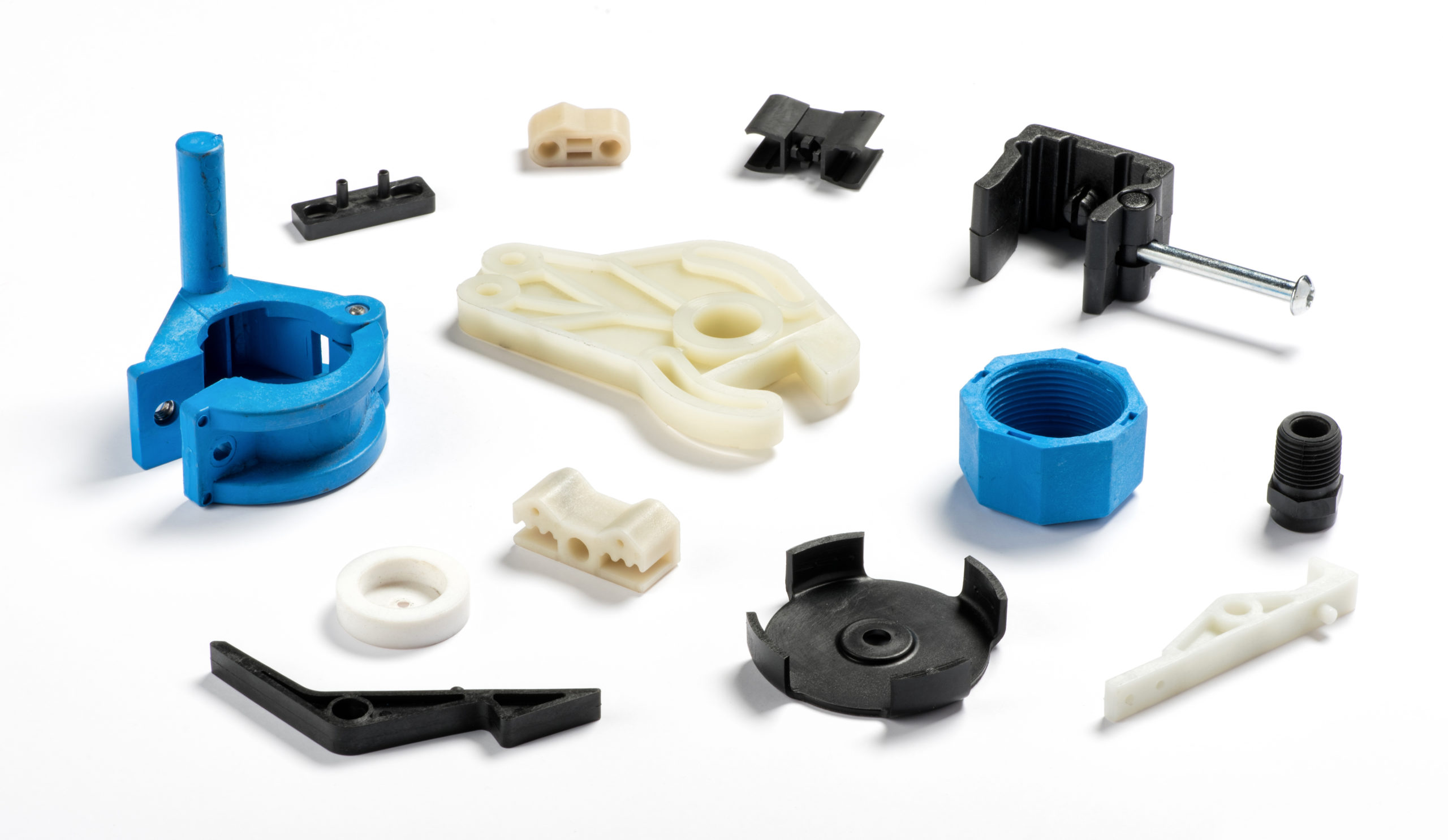

Injection molding is the number one way to make plastic parts in mass production and these are some of the best practices when designing for injection molding and how to get the most of this awesome process. Draft Draught is angled wall sections. the reason you need to have draught on an injection molded part is that if you don’t have draught, the part will not come out of the mold smoothly and it’ll leave scrape marks. also, if your part......

28

2021.5

What Is Polylactic Acid – Types, Applications, Advantages And Processes Of PLA

What is PLA stands for? PLA (polylactic acid) is the most mature, the most widely used and the lowest price bio-based plastics, which will become the ecological environmental protection materials with broad application prospects in the future. PLA is very environmentally friendly and has no pungent smell during processing. PLA is suitable for blow molding, thermoplastic and other processing methods. Here we highlight everything you need to know about PLA, the typ......