1. The machine has a heated barrel or hot runners where the plastic material melts.

2. After that, the liquid is injected into the mold with a single cavity (which is inside the device as well) using a mold injection where it is turned into a specific shape using injection molding design. The cycle time, injection time, wall thicknesses, injection pressures, and other parameters are fixed according to the design for manufacturability.

Plastic Injection Molding Machine

Injection molding machines are a critical part of the entire molding process. These machines have various components and different configurations like the vertical and the horizontal configuration. That said, the common components in any injection molding machine include the following:

1. The Injection Unit:

This part of the injection moulding machine works for heating as well as injecting the resins inside the plastic injection mould. The unit has various parts like a hopper, the barrel, ram injector, reciprocating crew, the screws, and the nozzle. The hopper is a large container with an open bottom that feeds the material to a barrel. The barrel, with a ram injector, forces the injection moulding material forward through a heated section. Reciprocating screws are used to propel the injection molding materials forward. The resins are then forced to enter the grooves in the screw and move towards the plastic injection mold. The heating channel melts the resins and the molten material gets injected into moulds using a nozzle at the end.

2. The Clamping Unit:

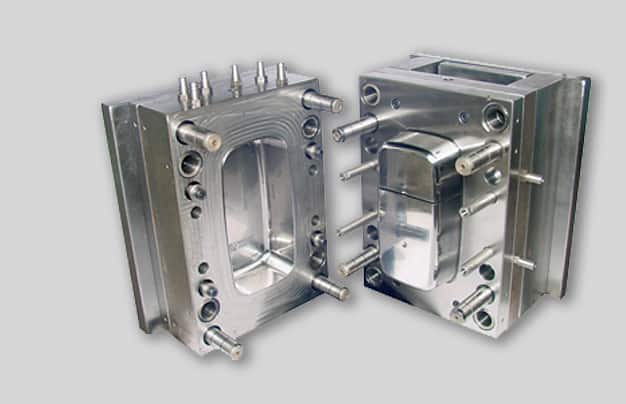

Moulds are usually created in two halves. Just prior to the injection process, the injection molds are clamped together. Each half needs to be fixed to the platen, which is a large plate-like structure. Once the injected molten resins are allowed the desirable cooling time, the molds are opened using a clamping motor.

The rear part of the mold has an ejection system with an ejection bar that pushed the solid plastic part out of the open cavity.

3. Mold Base:

A mold has two main parts: the mold core and the mold cavity. These two are together fixed to the platens of a mold base. The mold base on the front part has the support plate, the sprue bushing and a locating ring that aligns the mold base with the nozzle.

The rear part of the mold base has an ejection system as well as a support plate. The ejection system has an ejection bar, as mentioned earlier. As the name suggests, it helps in pushing the solidified plastic injection molds out of the mold cavity.

4. Mold Channels:

Mold channels are the pathways that the plastic resins take to flow into the mold cavities. These channels are integrated into the mold design to create a single piece.

The molten plastic enters through a channel called the sprue and then goes through other channels called the runners. The runners lead the plastic resin through a gate which throws the molten resin into the cavity.

Cooling channels are also sometimes created to allow the water to circulate along the mold walls and fasten the process of cooling the molten plastic.