The location of the parting line can affect your plastic molded part in several ways, it’s worth noting this problem. In this article, we’ll focus on the basics of parting lines in injection molding, covering what is it, the design of the parting line, and different types of forms.

What is a Parting Line in Injection Molding?

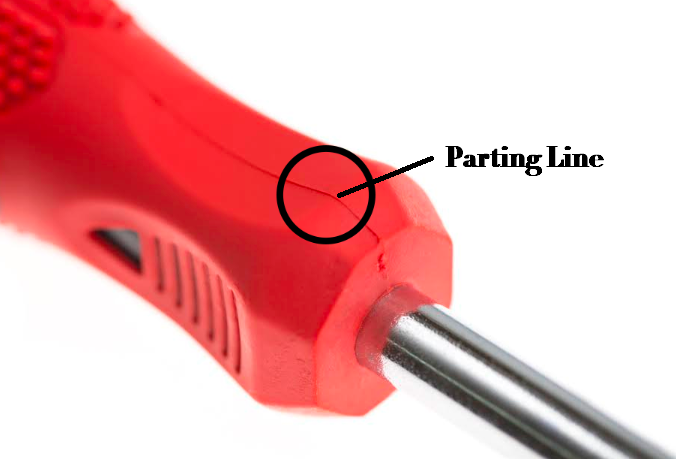

In plastic injection molding, a parting line is where two halves of a mold meet when closed. A plastic product formed by the injection mold is divided into two parts, and the line separating the product is called the parting line. Plastic is then injected at high pressure into the mold, and it solidifies with any surface features or defects in the mould. So in the case of the parting line, it will appear as an ever slightly raised line on the surface of the part. It is almost impossible to completely avoid or eradicate the parting line, but the effect can be reduced somewhat through the following solutions: camouflage the line by incorporating it with other parallel or linear design features; locate the parting line under a protruding feature like a rim or cap; disguise with rough surface textures and matte finishes; sand the lines smooth and repainted afterwards. Secondary operations to remove parting line flash including hand trimming, vibratory tumbling, media blasting and cryogenic deflashing.

What is the purpose of a parting line?

A parting line is a borderline in which draft angles change direction or a dividing line that splits the core and cavity halves of a molded part. It can also be used as a starting point for the mold parting surface.

Injection Molding Parting Line Design - How to Determine the Parting Line?

When determining the parting line, we must first determine the shape and position of the parting line on the plastic molded part. When the mold opening direction is determined, it is easier to determine the parting line. Because the projection of the parting line in the mold opening direction coincides with the outer contour of the projection of the plastic part in this direction, a straight line parallel to the mold opening direction can be moved along the outer contour projected by the object, and the intersection of the straight line with the object surface at each position can be calculated.

In addition, in the injection molding process of two-color mold, the determination of parting line depends on the design and appearance requirements of the product, and also considers whether the processing is feasible and the position of mold layout follow-up glue. It can be divided into the following three categories:

1. If the straight line intersects the object surface at a point, the point is the point on the parting line.

2. If the straight line intersects with the object surface in a straight line segment, any point of this straight line segment can be used as a point on the parting line. To determine which point is used as a point on the parting line, it is generally based on the principle of the shortest connecting line with adjacent points. It can also be determined interactively.

3. The line intersects with the object at multiple points and segments, indicating that the intersection of the global approach cone and the mold opening direction is 0, so the core pulling is designed in this area, and the mold parting line shall be determined according to the shape and size of the core pulling.

For complex parts, you can use tools within CAD packages to locate and evaluate the split lines, or use the suggested parting line, but it may not be the only option, consider whether its location will work both functionally and cosmetically.

Types of Parting Line in Injection Molding

There are different forms of parting lines depending on the design of the injection mold or plastic parts.

– Vertical parting line: it is formed in a perpendicular direction from the mold opening direction.

– Beveled parting line: as the name implies, the shape of the parting line is beveled.

– Curved parting line: as the name implies, the shape of the parting line is curved.

– Stepped parting line: machinists make the plastic parting line in a stepped shape. For this type of parting line, there is usually a large force on one side of the cavity. This leads to the possibility of relative sliding between the fixed and moving halves of the die. This force can then be offset by creating an injection force on both sides of the cavity.

– Comprehensive parting line: designed based on the structure of the plastic part, it can combine all other parting line forms.