With the continuous improvement of the performance of plastic raw materials, the proportion of plastic mold in the mold is increasing day by day, It has been widely used in the national economic departments and daily life, and the hot runner injection mold has been more and more widely used in developed countries and regions with its unique advantages.

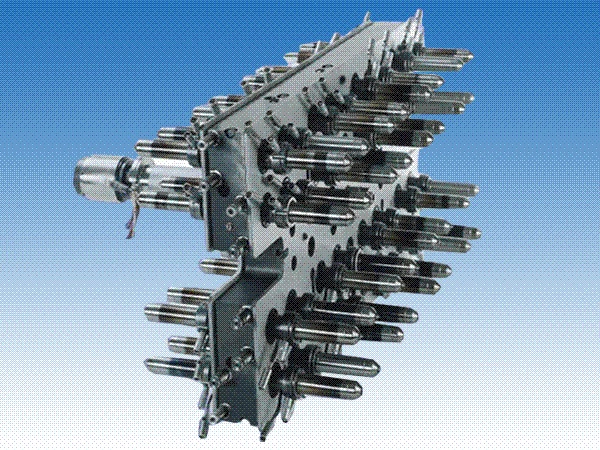

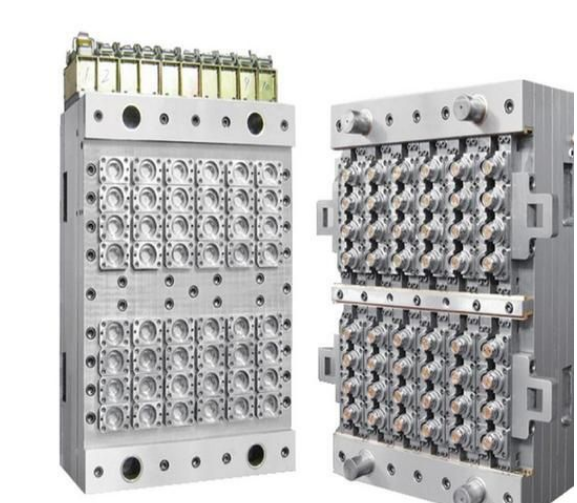

The hot runner is to ensure that the plastic in the runner and gate remains molten by heating. The hot runner system is generally composed of hot nozzle, distributor, temperature control box and accessories. While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice. Here we list some advantages and disadvantages of hot runner mould compare with cold runner system.

Benefits & Advantages Of Hot Runner Mold System

1. Shorten Cycle Time

Because there is no cooling time limit of runner system, the part can be ejected in time after solidification. Many thin-walled parts produced by hot runner injection mold can be formed in less than 5 seconds.

2. Save Plastic Materials

Because there is no cold runner in the hot runner mold, there is no production cost. This is particularly significant for the application of expensive plastic projects. In fact, the major hot runner manufacturers in the world have developed rapidly in the era of high price of petroleum and plastic raw materials. Because hot runner technology is an effective way to reduce the waste of material and reduce material cost.

3. Higher Product Quality

During the molding process of the hot runner mold, the plastic melt temperature is accurately controlled in the runner system. Plastic can flow into each cavity in a more uniform state, resulting in parts with consistent quality. The gate quality of the parts formed by the hot runner is good, the residual stress after demolding is low, and the part deformation is small. Therefore, many high-quality products on the market are produced by hot runner injection molds.

4. Design Flexibility

A major benefit of hot runner mold system of which very little is written is the ability to locate the gate at a wide variety of points on the part. With the use of hot tip gating, valve gating or edge gating, hot runners allow the gate to be placed at the most favorable location for optimum filling and/or part aesthetics. This flexibility that hot runners give the part design also extends to the mold, where flexibility in gate location can help optimize cavity orientation, cooling and mold simplification.

5. Conducive To Production Automation

After the parts are formed by the hot runner mold, they are finished products, and there is no need to trim the gate and recycle the cold runner, which is conducive to production automation. Many foreign product manufacturers combine hot runners with automation to greatly improve production efficiency.

Disadvantages Of Hot Runner Injection Molding System

Although hot runner mold system has many significant advantages over cold runner molds, mold users also need to understand the disadvantages of hot runner injection molds. To sum up, there are the following cons.

1. Higher Tooling Cost

The price of hot runner components is relatively expensive, and the cost of hot runner mold may be greatly increased. If the production of parts is small and the cost ratio of die and tool is high, it is not cost-effective in economy. For many mold users in developing countries, the high price of hot runner system is one of the main problems that affect the wide use of hot runner mold.

2. High Equipment Requirements

Requirements for the hot runner mold manufacturing process are high The hot runner mold needs precision machining machinery to ensure. The integration and cooperation requirements of hot runner system and mold are very strict, otherwise there will be many serious problems in the production process.

3. Complicated Operation And Repairment

Compared with the cold runner mold, hot runner is hard to operate and repair. If it is used improperly, it is easy to damage the hot runner parts, which makes the production impossible. It caused huge economic losses. For new users of hot runner mold, it will take a long time to accumulate experience.