Hot runner in injection molding acts as a feed system of the liquid plastic and deliver the material to mold cavities. The design of hot runner mold makes it beneficial to the creation of plastic molded parts. In this article, let’s see what is hot runner system and what advantages it has.

What is Hot Runner System in Injection Molding?

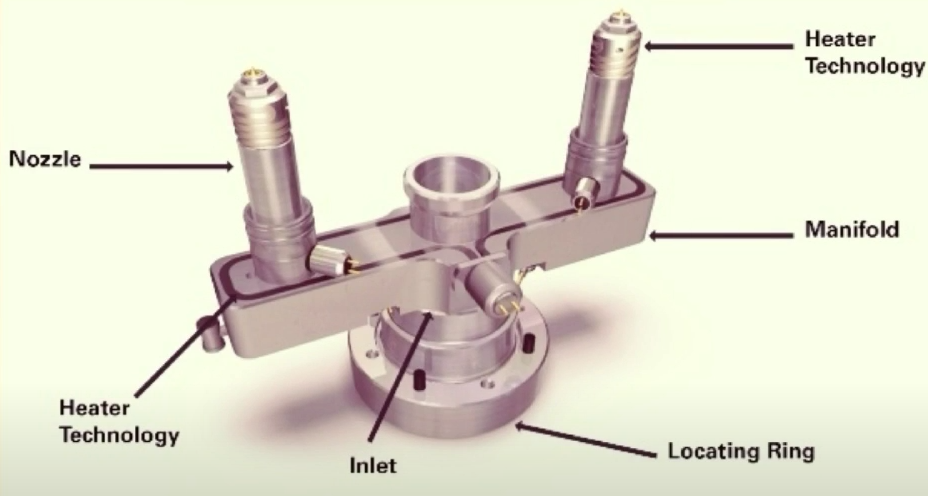

The hot runner system is an assembly of heated components used in plastic injection molds that inject molten plastic into the cavities of the mold. It usually consists of a heated manifold and a number of heated nozzles. The main purpose of the manifold is to distribute the plastic entering the mold to the various nozzles which then meter it precisely to the injection points in the cavities. The hot runner molding process keeps the runners hot to maintain the plastic in a molten state throughout the whole process.

Parts of hot runner system:

Benefits and Advantages of Injection Molding Hot Runner System

Compared to cold runner system, why we choose hot runner system?

1. Improved efficiency

The hot runner mold is generally easier to start because there aren’t any solidified runners or removing after each shot, this like say you got a partner running it, you got to take the runner out every single time, this means you can run it a lot faster, automatic cycles can begin faster.

2. Design flexibility

A major hot runner advantage is the ability to locate the gates at a wide variety of different points on a part, so if you have a part that’s really big, you can actually put your valve gates anywhere you want because you can make the design of this, that’s your design flexibility.

3. Balanced melt flow

The melt channels are in separate heated manifolds, you got this whole channel with a manifold and then drops that come off of the manifold, then you got a sprue bushing heater, this is the thing on the balance, you’re getting the same distance when it fills in from whatever.

4. Shorten cycle time

The forming cycle of the parts is shortened. Because there is no restriction on the cooling time of the sprue system, the parts can be ejected in time after forming and curing. The forming cycle of many thin-walled parts produced by hot runner mold can be less than 5 seconds.

5. Save plastic materials

In the pure hot runner mold, there is no cold runner, so there is no production waste. This is especially significant for the projects with expensive plastic prices. In fact, the major international hot runner manufacturers have developed rapidly in the era of expensive oil and plastic raw materials in the world. Because hot runner technology is an effective way to reduce material cost.

6. Reduce waste

Reduce waste products and improve product quality. In the hot runner mold forming process, the plastic melt temperature is accurately controlled in the runner system. The plastic can flow into each mold cavity in a more uniform state, resulting in parts with the same quality. The gate quality of the parts formed by hot runner is good, the residual stress is low after demoulding, and the deformation of the parts is little.

7. Production automation

Eliminate subsequent processes, which is conducive to production automation. The finished product is formed by the hot runner mold, and there is no need to trim the gate and recycle the cold sprue. It is conducive to production automation.

8. Optimal quality

When the plastic flows through the cold runner system, there’s less heat that you’re using actually on this part, causing pressure drops that can result in sink marks and unfilled parts. A hot runner system on the other hand maintains a balanced melt flow and consistent temperature from the machine nozzles all the way through the gate and fully into the pack and hold of each cavity.